Universal Testing Machines (UTMs) are fundamental instruments in material testing laboratories across industries. They provide critical data for evaluating the mechanical properties of various materials, including metals, plastics, rubber, composites, and more. Whether you are testing for tensile strength, compressive resistance, or material elongation, a UTM ensures consistent, repeatable, and accurate results that support quality assurance, research and development, and international compliance with standards such as ASTM, ISO, and GB/T.

What Is a Universal Testing Machine?

A Universal Testing Machine, also known as a UTM, is a multi-purpose device designed to apply controlled tensile or compressive force to a test specimen until failure. It evaluates key mechanical properties such as:

Tensile strength

Yield strength

Compressive strength

Elongation at break

Young’s modulus (modulus of elasticity)

UTMs are commonly used in industries like metallurgy, construction, automotive, aerospace, and plastics manufacturing, where understanding material behavior under stress is critical to product performance and safety.

How to Perform a Tensile Test Using a Universal Testing Machine

Tensile testing is one of the most widely used procedures for determining how a material reacts under pulling forces. Here is a step-by-step breakdown of the tensile testing process using a UTM:

1. Prepare the Test Specimen

Specimens must be machined or molded to standardized dimensions and shapes based on testing standards such as ASTM E8 (for metals) or ISO 6892. Proper surface finish and dimensional accuracy are essential to achieve reliable test results.

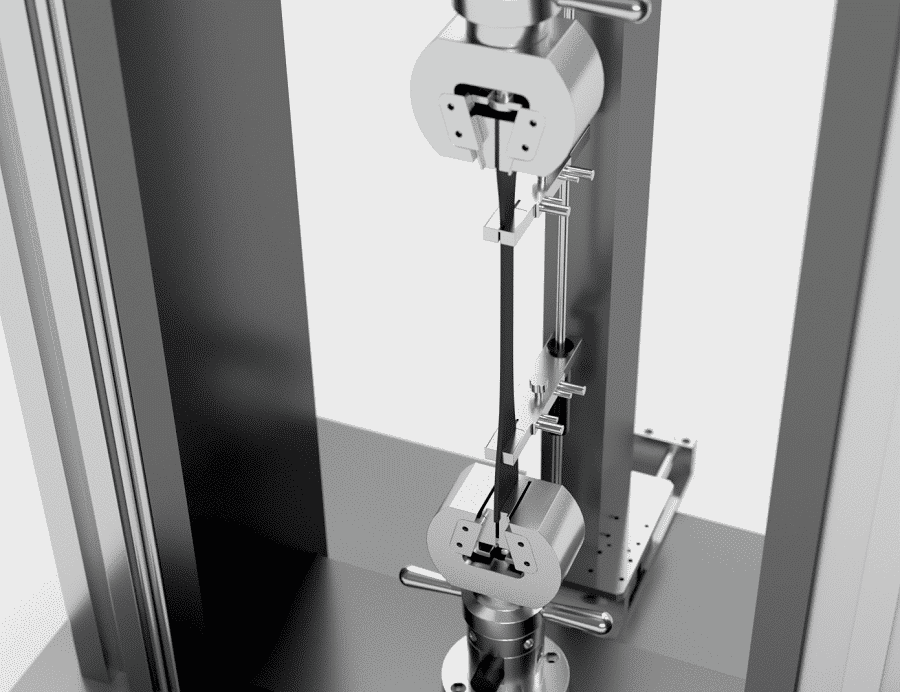

2. Select and Install the Appropriate Grips

The correct grips are crucial to prevent specimen slippage or premature failure. Options include wedge grips, hydraulic grips, or pneumatic grips, depending on the material type (e.g., flat, round, thin film).

3. Calibrate the Machine

Before testing, calibrate the load cell and extensometer according to the relevant standard. This step ensures accurate force and elongation readings throughout the test.

4. Set Test Parameters in the UTM Software

Input parameters such as:

Gauge length

Test speed (crosshead rate)

Preload value

Data acquisition rate

These settings should match the testing standard and material behavior.

5. Conduct the Test

Start the UTM. The machine applies a constant speed to pull the specimen until it fractures. Throughout the process, real-time force and elongation data are recorded.

6. Analyze the Results

After the test, the system generates a stress-strain curve, from which key properties like tensile strength, yield point, modulus of elasticity, and total elongation are derived.

How to Perform a Compression Test Using a Universal Testing Machine

Compression testing is vital for evaluating materials like concrete, foam, metals, elastomers, and packaging components. It determines how a material behaves under crushing loads.

1. Attach Compression Platens or Fixtures

Depending on the specimen geometry, install flat compression platens or custom jigs. The contact surfaces must be clean, flat, and well-aligned.

2. Align the Specimen Carefully

Misalignment during setup is one of the leading causes of invalid results. Use centering tools or guides to ensure uniform force distribution.

3. Configure Test Settings

Set an appropriate compression speed based on the material. Soft materials like foam may require slower speeds (1–5 mm/min), while metals can be tested at higher rates (10–50 mm/min).

4. Monitor the Test

During compression, the UTM records data such as maximum load, deformation, and failure mode. Visual inspection can reveal buckling, cracking, or material crushing behavior.

Why Universal Testing Matters

Accurate mechanical testing with a UTM provides critical insights into how materials and components will perform in real-world applications. This data is essential for:

Ensuring product safety and durability

Verifying compliance with international standards

Supporting material selection for design optimization

Enabling predictive maintenance and failure analysis

For industries like aerospace, automotive, or biomedical engineering, even slight variations in tensile or compressive performance can have serious consequences.