Mechanical Testing Machines: Precision Tools for Material Evaluation

Mechanical testing machines are essential instruments used across industries to determine the physical and mechanical properties of materials. These machines apply controlled forces to materials such as metals, plastics, ceramics, composites, and elastomers to evaluate their strength, durability, and suitability for specific applications. From research laboratories to manufacturing plants, mechanical testing machines provide the data necessary for product development, quality assurance, and regulatory compliance.

Mechanical testing plays a crucial role in various sectors, including aerospace, automotive, civil engineering, energy, medical devices, and construction. Every component used in these industries must meet specific mechanical performance criteria to ensure safety, reliability, and cost-efficiency. Testing machines enable engineers and researchers to verify material properties such as tensile strength, elongation, modulus of elasticity, fracture toughness, hardness, impact resistance, and fatigue life.

Modern mechanical testing machines are highly versatile and are often equipped with computer-controlled systems, digital sensors, extensometers, load cells, and custom fixtures. These systems provide real-time data acquisition and analysis, allowing precise control over test parameters and conditions. Test results are often used to certify materials against international standards such as ASTM, ISO, DIN, and JIS.

Why Mechanical Testing Machines Are Critical to Material Validation

Mechanical testing provides accurate, repeatable and standardized assessment of a material’s strength, stiffness, toughness and durability. Testing instruments provide quantifiable, objective data without relying on subjective or inconsistent methods.

Types of Mechanical Testing Machines

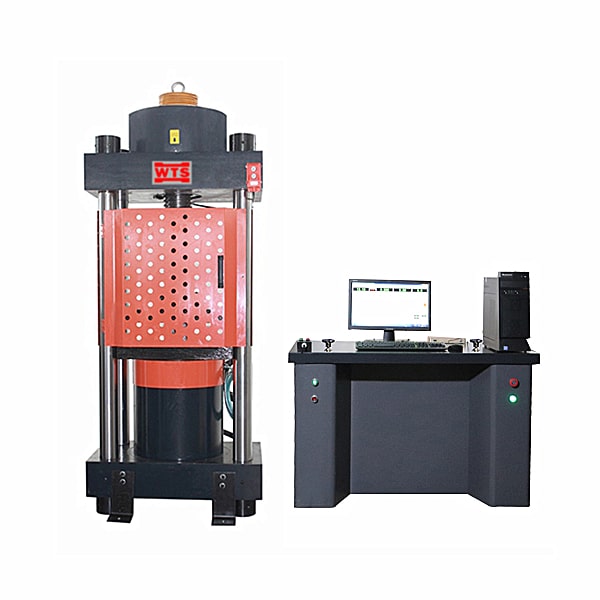

Mechanical testing machines come in a wide variety of types, each designed for specific test methods and force ranges. The two most common categories are electromechanical and servo-hydraulic systems.

Electromechanical Testing Machines are typically used for low to medium force applications and offer precise control over displacement and speed. These machines use motor-driven screws to move the crosshead and are ideal for tests such as tensile, compression, bending, shear, peel, and puncture. They are widely used in research labs and educational institutions due to their user-friendly interface and high accuracy.

Servo-Hydraulic Testing Machines are used for high-force and dynamic testing. They operate using hydraulic actuators controlled by servo valves, making them suitable for fatigue, fracture mechanics, and high-rate loading tests. These machines are essential in industries that require high-strength materials, such as aerospace, automotive crash testing, and structural engineering.

In addition to universal testing machines, other types of mechanical testing equipment include:

- Impact Testing Machines: Used for Charpy and Izod tests to determine material toughness at various temperatures.

- Hardness Testers: Used to measure the resistance of materials to surface indentation using methods like Brinell, Rockwell, Vickers, and Knoop.

- Torsion Testing Machines: Used to apply rotational forces to determine shear strength and angular deformation.

- Fatigue Testing Machines: Designed to simulate cyclic loading over time to determine the endurance limit of a material.

- Creep Testing Machines: Used to measure time-dependent deformation under constant stress and temperature.

Common Mechanical Testing Methods

Mechanical testing covers a broad spectrum of methods, each designed to evaluate a specific property of a material. The most common mechanical tests include:

Tensile Testing is the most widely performed mechanical test. It involves stretching a specimen until it fractures to determine properties such as yield strength, tensile strength, modulus of elasticity, and elongation. Tensile tests provide fundamental data for material comparison and design.

Compression Testing determines a material’s ability to withstand compressive forces. It is commonly used for testing concrete, ceramics, rubber, and metals in structural applications.

Flexural (Bend) Testing evaluates a material’s behavior under bending loads. It is often used for plastics, composites, and wood products to measure flexural strength and stiffness.

Shear Testing measures the material’s response to forces applied parallel to its surface. This method is particularly relevant for adhesives, welds, and fasteners.

Tear and Peel Testing are performed on flexible materials such as films, fabrics, and tapes to determine their resistance to tearing or peeling apart.

Impact Testing, including Charpy and Izod tests, assesses the energy absorbed by a material during a high-speed impact. This property is vital for applications where shock loading occurs, especially at low temperatures.

Hardness Testing evaluates surface hardness using indentation methods. It provides insight into a material’s wear resistance and is widely used in metal processing and quality control.

Fatigue Testing subjects a material to repeated loading cycles to determine its durability over time. It is essential for components that experience fluctuating stresses during service.

Creep Testing measures the slow deformation of a material under constant load and high temperature over an extended period. This is crucial for evaluating heat-resistant materials used in power plants, jet engines, and turbines.

Applications Across Industries

Mechanical testing machines are used in virtually every industry that requires the use of materials or components under mechanical stress. Below are examples of their applications across various fields:

Aerospace Industry: Aircraft components must meet strict safety standards. Mechanical tests validate the performance of metals, composites, and fasteners under extreme temperature and pressure conditions.

Automotive Industry: Vehicles must endure dynamic loads, vibrations, and impact. Mechanical testing ensures that chassis components, crash structures, suspensions, and interior materials meet performance requirements.

Construction and Infrastructure: Structural steel, concrete, asphalt, and rebar are tested to ensure they can bear the loads required in bridges, tunnels, and buildings.

Medical Devices: Implants, surgical tools, and prosthetics must be biocompatible and mechanically reliable. Testing ensures materials can withstand forces in the human body.

Energy Sector: Wind turbine blades, oil pipelines, nuclear components, and solar panel mounts undergo fatigue, tensile, and impact testing to ensure long-term reliability.

Electronics and Consumer Products: Components such as casings, wires, connectors, and battery housings are tested for drop resistance, bending, and tensile strength.

Textile and Packaging: Fabrics, films, and adhesives are tested for tensile strength, tear resistance, peel strength, and puncture resistance to ensure durability and usability.

Choosing and Using Mechanical Testing Equipment

When selecting a mechanical testing machine, several factors must be considered:

Material Type and Form: The physical properties, geometry, and behavior of the test material will determine machine capacity, grip design, and test method.

Force Range: Testing machines come in capacities ranging from a few newtons to several meganewtons. Choose according to the expected load.

Test Method: Whether it’s tensile, flexural, compression, or fatigue testing, the machine must be compatible with relevant fixtures and transducers.

Compliance with Standards: Ensure that the machine and test methods conform to ASTM, ISO, EN, or other required standards.

Data Acquisition System: Modern systems include digital controllers, real-time display of force-displacement curves, automatic calculations, and report generation.

Environment: For tests requiring temperature or humidity control, choose machines compatible with environmental chambers.

Safety Features: Emergency stops, overload protection, and guarding are critical to operator safety.

Service and Support: Availability of local technical support, calibration services, spare parts, and training should be evaluated.

Future Trends and Digital Integration

Mechanical testing technology is evolving with the integration of digital tools, automation, and data connectivity. Several trends are shaping the future of mechanical testing:

Smart Testing Systems: Machines now offer predictive maintenance alerts, automatic calibration prompts, and intelligent diagnostics.

IoT and Industry 4.0: Test systems are connected to factory networks, allowing real-time monitoring, centralized control, and remote troubleshooting.

AI-Driven Data Analysis: Artificial intelligence is being used to identify anomalies, optimize test parameters, and forecast material performance.

Green Testing: Energy-efficient machines, reduced oil consumption, and recyclable components are gaining importance in sustainable labs.

Modular Equipment: Machines with interchangeable test modules and multi-axis testing capabilities offer flexibility across test types.

Cloud-Based Reporting: Test results are uploaded to secure servers, allowing stakeholders to view, analyze, and archive data from anywhere.