What Is a Universal Testing Machine?

A Universal Testing Machine (UTM) is a mechanical testing device used to determine the tensile, compressive, and flexural strength of materials. The term “universal” indicates its capability to perform multiple types of tests on a wide range of materials, including metals, plastics, rubber, textiles, composites, and more. UTMs are essential in quality control, research and development, product certification, and education.

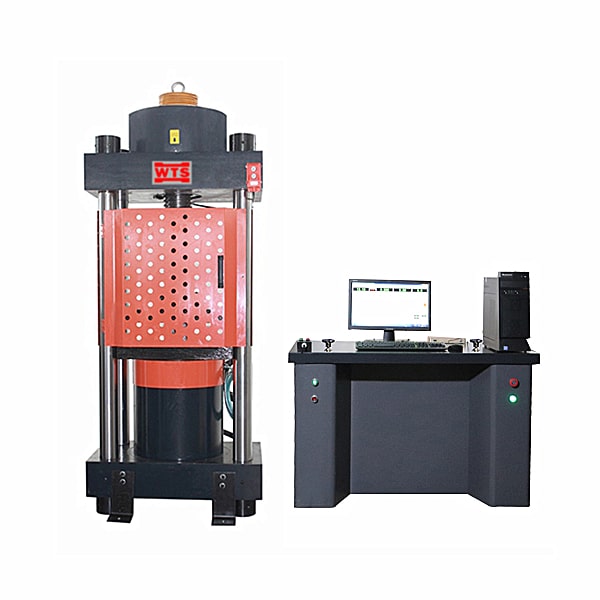

Typically, a UTM consists of a load frame, crosshead, load cell, grips or fixtures, extensometers, and a digital control system. The test specimen is held between two grips; the crosshead applies controlled force through tension or compression. Advanced UTMs are equipped with software that enables real-time data acquisition, stress-strain analysis, and report generation.

UTMs can be classified based on their drive mechanism: electronic UTMs are powered by servo motors and are commonly used in laboratories, while hydraulic UTMs are suited for heavy-duty testing of high-strength materials in industrial settings.

Applications Across Industries

Metal and Alloy Testing

UTMs are widely used for testing the mechanical properties of metals and alloys such as steel, aluminum, titanium, and copper. These tests conform to standards like ASTM E8/E8M and ISO 6892. Properties evaluated include yield strength, tensile strength, elongation, and modulus of elasticity.

Plastics and Polymers

In industries dealing with thermoplastics, thermosetting polymers, and elastomers, UTMs determine tensile modulus, breaking strength, and elongation at break. Standards like ASTM D638 and ISO 527 are commonly used.

Rubber and Elastomers

UTMs measure tensile and tear resistance for rubber materials used in seals, tires, and gaskets. These tests conform to ASTM D412 and ISO 37.

Textile and Fabric Testing

UTMs assess tensile strength, seam slippage, and bursting strength of woven and non-woven fabrics. Standards include ASTM D5035 and ISO 13934-1.

Composites and Advanced Materials

For aerospace, automotive, and sporting goods industries, UTMs analyze tensile, flexural, and shear properties of fiber-reinforced composites. These tests often use ASTM D3039 and ISO 14125.

Choosing the Right UTM

Define Your Testing Needs

The first step is to determine your specific testing requirements:

What material types will be tested?

What is the expected range of test loads?

What types of tests are required (tensile, compression, flexural)?

What test standards must be followed?

Will you require automatic data analysis and reporting?

Consider Load Capacity and Accuracy

UTMs are available in a wide range of load capacities, from 1 kN to over 2000 kN. For precise testing, choose a UTM with high accuracy (Class 0.5 or Class 1 per ISO 7500-1 or ASTM E4). Load cells and extensometers should also meet international calibration standards.

Software and Control System

Modern UTMs come with powerful software for test control, data acquisition, and analysis. Features to consider:

User-friendly interface

Support for multiple test standards

Customizable test templates

Real-time graph plotting

Data export in Excel, PDF, or CSV

Fixtures and Accessories

The choice of grips and fixtures greatly affects test accuracy and repeatability. Options include:

Wedge grips for metals

Pneumatic grips for thin specimens

Compression platens

Bend test fixtures

Custom jigs for special samples

Service and Calibration Support

Choose a manufacturer or supplier that offers:

On-site installation and training

Annual calibration services

Spare parts and consumables

Local or remote technical support

Leading Global and Chinese Manufacturers

Several global brands dominate the UTM market, including:

Instron (USA): Known for modular design and automation

ZwickRoell (Germany): Specializes in high-speed testing systems

MTS Systems (USA): Focuses on high-capacity dynamic testing

Shimadzu (Japan): Offers compact, precise machines

In China, cost-effective and high-performance UTMs are available from:

Jinan Wenteng Testing Instrument Co., Ltd.: Offers customizable solutions with strong after-sales service

Wance Technologies and Suns Technology: Known for mass production and export