A Universal Testing Machine (UTM) is a versatile instrument used for determining the mechanical properties of materials under tension, compression, bending, and shear. Among the most widely adopted tensile testing standards for plastics and polymers are ASTM D638 and ISO 527.

Both standards define the procedure for measuring tensile strength, elongation, and modulus of plastics. Choosing a UTM that complies with these standards ensures reliable test results, regulatory compliance, and confidence in material performance.

What is a Universal Testing Machine?

A Universal Testing Machine (UTM) is a material testing instrument designed to:

Apply controlled tension or compression to a specimen

Measure load, displacement, and strain with high accuracy

Evaluate tensile, compressive, flexural, and shear properties

ASTM D638 – Tensile Properties of Plastics

Issued by: ASTM International (American Society for Testing and Materials)

Scope: Tensile testing of plastics under ambient conditions

Specimens: Dog-bone shaped specimens (Types I–V)

Test speed: Depends on material stiffness and thickness

ISO 527 – Tensile Testing of Plastics

Issued by: International Organization for Standardization (ISO)

Scope: Tensile testing of plastics, films, and composites

Specimens: Dumbbell-shaped specimens (ISO 527-2/3/4/5)

Test speed: Based on strain rate requirements

ASTM D638 vs ISO 527: Key Differences

| Feature | ASTM D638 (Plastics) | ISO 527 (Plastics & Composites) |

|---|---|---|

| Governing body | ASTM International (USA) | ISO (International) |

| Specimen shape | Dog-bone (Type I–V) | Dumbbell (ISO 527-2/3/4/5) |

| Speed definition | Crosshead speed | Strain rate |

| Primary region | North America | Europe & Global markets |

Why UTM is Essential for ASTM D638 & ISO 527

A UTM configured for ASTM D638 and ISO 527 tensile testing requires:

High-precision load cell – for accurate force measurement

Extensometer or video extensometer – for precise strain measurement

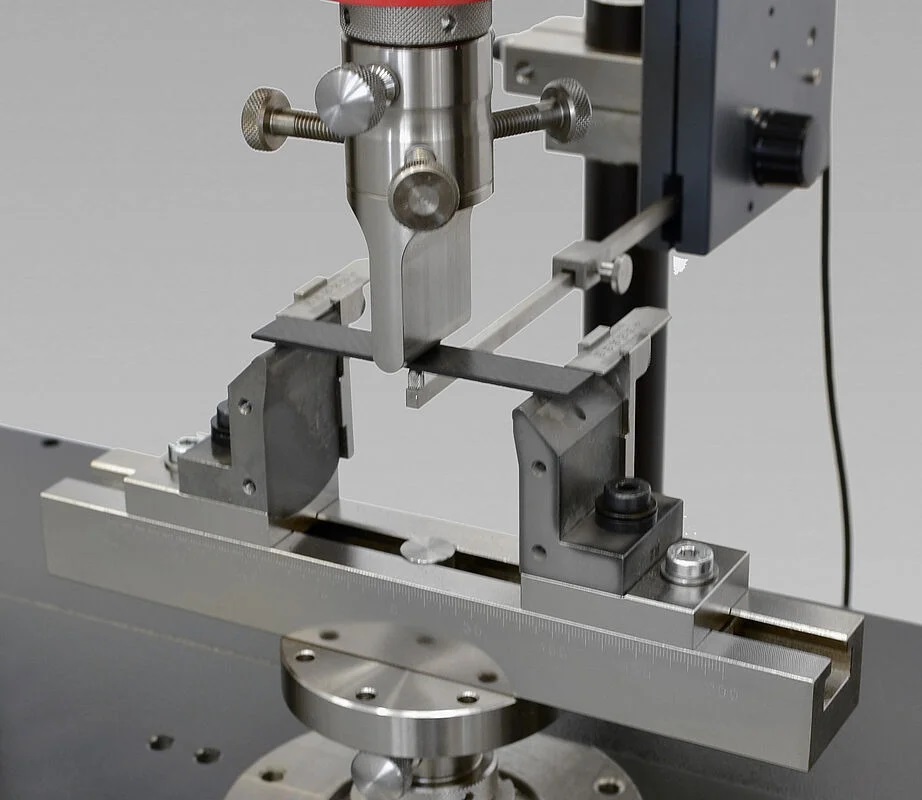

Tensile grips – to hold dog-bone or dumbbell specimens securely

Testing software – with built-in ASTM D638 and ISO 527 templates

FAQ

Q1: What is the difference between ASTM D638 and ISO 527?

ASTM D638 is widely used in North America, while ISO 527 is the international and European equivalent. The main differences lie in specimen geometry and testing speed definitions.

Q2: Can one UTM perform both ASTM D638 and ISO 527 tests?

Yes. A properly configured UTM with the correct grips, extensometers, and software can support both standards.

Q3: What grips are recommended for plastic tensile tests?

Wedge grips or pneumatic grips are commonly used to prevent specimen slippage.

Q4: What data does ASTM D638 and ISO 527 provide?

Both standards provide tensile strength, elongation at break, modulus of elasticity, and yield point data.