A Universal Testing Machine (UTM) is a versatile instrument capable of performing tensile, compression, bending, and shear tests. When it comes to evaluating the flexural properties of plastics, the most widely recognized international standards are ASTM D790 and ISO 178.

Both standards define methods for determining the flexural strength, flexural modulus, and deformation behavior of plastics under a three-point bending load. Selecting a UTM that complies with ASTM D790 and ISO 178 ensures accurate results and compliance with international testing requirements.

What is a Flexural Test?

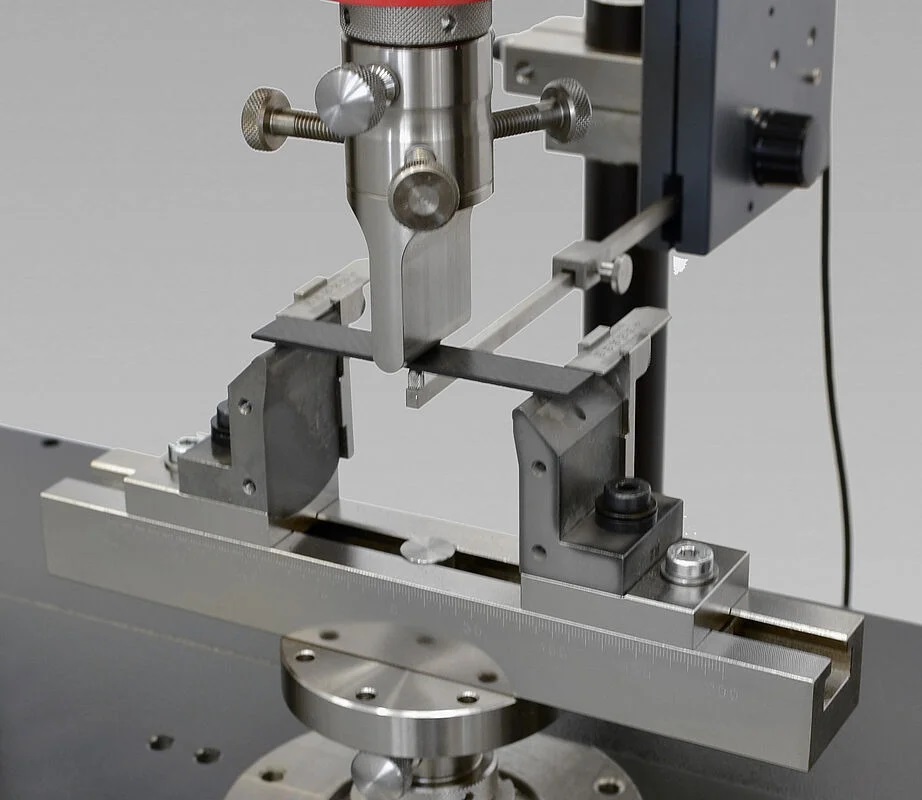

A flexural test measures a material’s ability to resist deformation under load. Using a three-point or four-point bending setup, a specimen is supported at both ends while a force is applied in the middle.

Key parameters obtained:

Flexural strength (stress at rupture)

Flexural modulus (slope of stress–strain curve)

Deflection at break or yield

ASTM D790 – Flexural Properties of Plastics

ssued by: ASTM International (USA)

Scope: Measures flexural strength and modulus of plastics using three-point bending

Specimens: Rectangular bars, dimensions based on material type and thickness

Test speed: Depends on specimen thickness and strain rate

ASTM D790 vs ISO 178: Key Differences

| Feature | ASTM D790 | ISO 178 |

|---|---|---|

| Governing body | ASTM International (USA) | ISO (International) |

| Specimen type | Rectangular bar | Rectangular bar |

| Test method | 3-point bending | 3-point bending |

| Test speed | Defined by crosshead rate | Defined by strain rate |

| Region of use | North America | Europe / Global markets |

Why UTM is Essential for ASTM D790 & ISO 178

To comply with ASTM D790 and ISO 178, a UTM must be equipped with:

High-precision load cell (for force measurement)

Bending fixtures (three-point or four-point)

Deflection measurement system (crosshead displacement or extensometer)

Software with ASTM D790 and ISO 178 methods pre-programmed

FAQ

Q1: What is the difference between ASTM D790 and ISO 178?

ASTM D790 is more common in North America, while ISO 178 is widely used in Europe and internationally. The main difference lies in the way test speed is defined.

Q2: Can one UTM perform both ASTM D790 and ISO 178 tests?

Yes. With proper fixtures and software, a single UTM can perform both standards.

Q3: What type of specimen is used for ASTM D790 and ISO 178?

Rectangular bar-shaped specimens, typically cut or molded from the test material.

Q4: What properties are measured in flexural tests?

Flexural strength, flexural modulus, and deflection/strain at break.

Q5: Which industries need flexural property testing?

Automotive, aerospace, plastics, packaging, and construction industries commonly require flexural tests.