ASTM D638 is one of the most widely used international standards for testing the tensile properties of plastics. It provides detailed procedures to measure the tensile strength, yield strength, elongation, and modulus of elasticity of plastic materials.

To comply with ASTM D638, a Universal Testing Machine (UTM) is required. This equipment applies a controlled tensile force on a specimen until it breaks, recording the force and elongation throughout the process.

Why Use a Universal Testing Machine for ASTM D638?

A Universal Testing Machine (UTM), also known as a tensile testing machine, is designed to perform a wide range of mechanical tests including:

Tensile Test – to measure ultimate tensile strength (UTS) and elongation.

Compression Test – to determine compressive strength.

Flexural Test – for bending properties.

Shear Test – for material shearing resistance.

When performing ASTM D638, the UTM must be equipped with:

Precise load cell to measure force.

Extensometer or video extensometer to measure strain accurately.

Standardized ASTM D638 dumbbell-shaped specimens.

Key Parameters Measured in ASTM D638

Using a Universal Testing Machine, ASTM D638 helps determine:

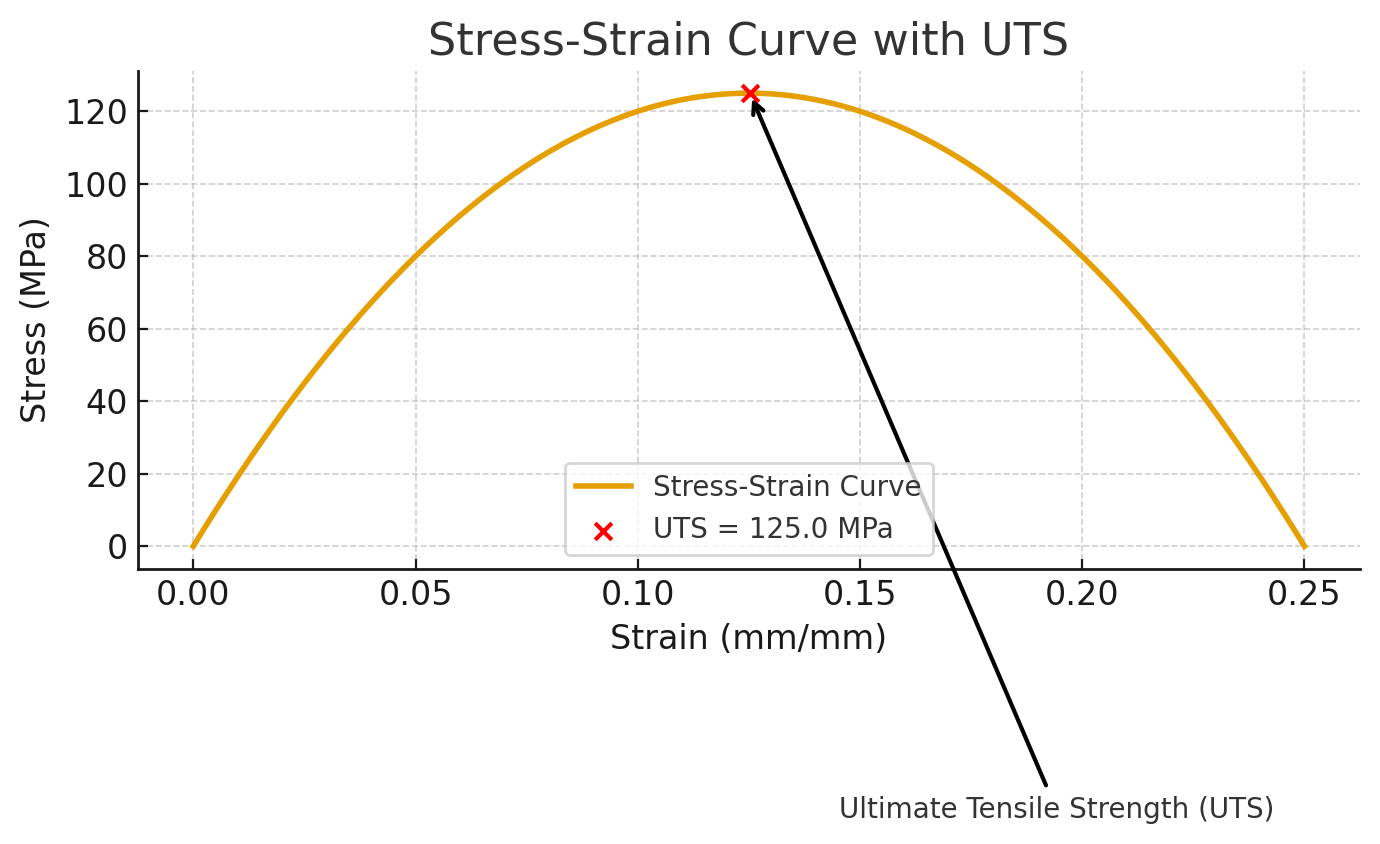

Tensile Strength (MPa or N/mm²) – the maximum stress the material can withstand.

Yield Strength – the stress at which plastic deformation begins.

Elongation at Break (%) – how much the specimen can stretch before failure.

Young’s Modulus (Elastic Modulus) – stiffness of the material.

Applications of ASTM D638 Testing

ASTM D638 testing is widely applied in industries such as:

Plastics manufacturing (thermoplastics, thermosets, composites)

Automotive (plastic parts, interior materials)

Aerospace (lightweight composites)

Medical devices (plastic tubing, prosthetics)

Construction materials (PVC pipes, polymer sheets)

Benefits of Using ASTM D638 Compliant UTM

Ensures international standard compliance.

Provides accurate and repeatable results.

Helps with R&D, quality control, and certification.

Enhances material reliability and safety.

Conclusion

The ASTM D638 Universal Testing Machine is essential for evaluating the tensile properties of plastics and polymers. By following ASTM D638 procedures, manufacturers and researchers can ensure their materials meet global quality standards, improve product performance, and maintain consistency in production.

If you are in the plastics, automotive, or aerospace industry, investing in a reliable Universal Testing Machine is crucial for staying competitive and ensuring compliance with international testing standards.