In the field of materials testing, ASTM E8/E8M and the Universal Testing Machine (UTM) are inseparable. ASTM E8/E8M is one of the most widely used international standards for metal tensile testing, while the UTM is the essential equipment that makes the test possible. Understanding their history and connection is crucial for laboratories, manufacturers, and research institutions.

The Origin of ASTM E8/E8M

The first edition of ASTM E8 was introduced in 1924 by ASTM International to standardize tensile testing methods for metallic materials. Later, to support global adoption, the metric version ASTM E8M was added. Today, ASTM E8/E8M remains the most authoritative reference for tensile testing worldwide.

The standard defines:

Specimen geometry and preparation

Loading rate and testing procedures

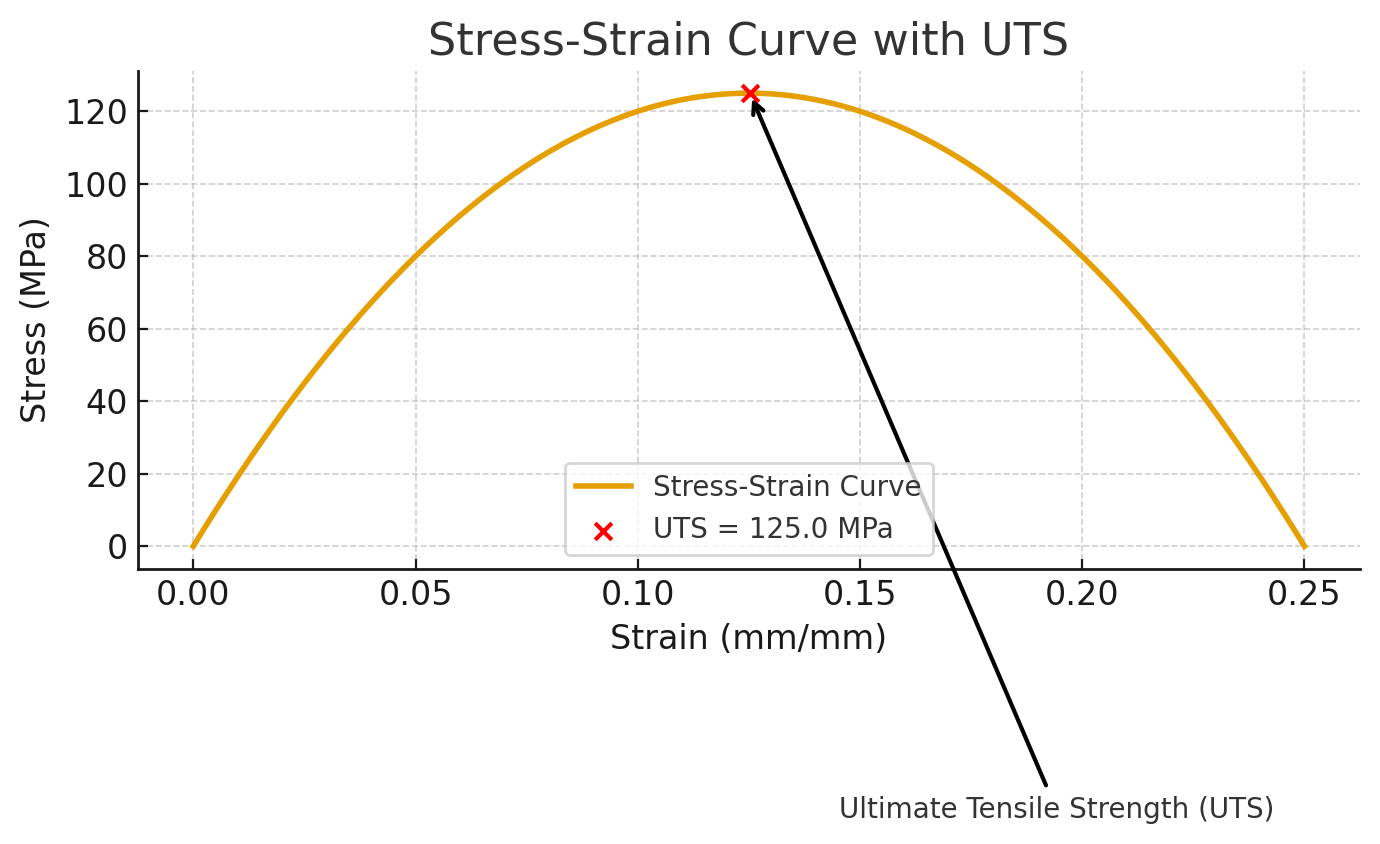

Data analysis methods for ultimate tensile strength (UTS), yield strength, elongation, and reduction of area

The key difference is unit usage:

ASTM E8 uses inch–pound (imperial) units

ASTM E8M uses metric (SI) units

The Development of Universal Testing Machines

Before ASTM E8 was widely adopted, metal tensile testing was often performed with rudimentary devices, leading to inconsistent results. With the rise of industrialization in the mid-20th century, the Universal Testing Machine (UTM) became the standard testing instrument.

Modern UTMs offer several advantages:

Versatility – capable of tensile, compression, and bending tests.

High-precision load cells – ensuring reliable force measurements.

Controlled loading rates – essential for ASTM compliance.

Automation and digital software – enabling standardized data reporting and analysis.

The Connection Between ASTM E8/E8M and UTM

Over time, the integration of ASTM standards with advanced testing machines created consistency across industries.

In research laboratories: UTMs provide repeatable and precise tensile data following ASTM E8/E8M.

In industrial production: UTMs ensure batch quality control and compliance with ASTM standards.

In global trade: ASTM-compliant tensile reports increase international acceptance and competitiveness of products.

Practical Applications Today

ASTM E8/E8M tests using a Universal Testing Machine are now standard practice in:

Steel and aluminum manufacturing

Automotive and aerospace engineering

Construction and infrastructure projects

Universities and research centers

Conclusion

The evolution of ASTM E8/E8M provided a globally recognized framework for metal tensile testing, while the development of the Universal Testing Machine supplied the technology to execute the standard effectively. Together, they have shaped modern materials science and engineering.

For companies, investing in a UTM that fully complies with ASTM E8/E8M ensures accurate results, international recognition, and enhanced product reliability—a critical step for quality assurance and global market expansion.