Types of Universal Testing Machines: A Complete Guide 1. Classification by Drive Mechanism One of the most common ways to classify Universal Testing Machines (UTMs) is based on the drive system that applies force during testing. Each type is suited for specific test ranges and applications. 1.1. Electro-Mechanical (Electronic) UTM This type…

Understanding the Role of UTMs in Concrete Testing Concrete is one of the most widely used construction materials globally, prized for its strength, durability, and versatility. To ensure concrete meets the structural requirements of buildings, roads, and bridges, it must undergo rigorous mechanical testing. One of the most reliable tools…

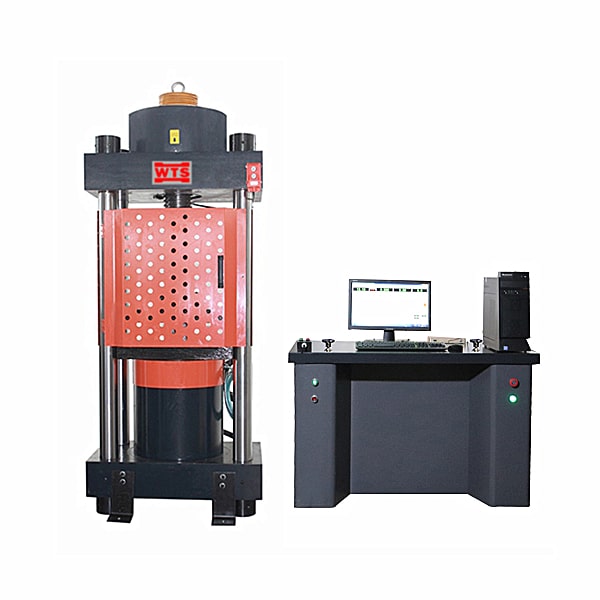

Metals and Heavy Engineering Hydraulic Universal Testing Machines (UTMs) are the go-to solution for testing high-strength materials due to their superior load capacity—ranging from 300 kN to over 2000 kN. They are widely used in the metallurgical, steel, mining, and construction equipment industries. Common applications include: Tensile testing of steel…

Fatigue Testing Machines are indispensable tools in modern engineering, allowing industries to simulate and analyze the behavior of materials and components under repeated or fluctuating loads. These machines provide critical data on how long a product can endure stress cycles before failure—information that is vital for ensuring safety, reliability, and…

In today’s rapidly advancing technological landscape, automation and precision play crucial roles in improving the efficiency and accuracy of processes across industries. One such technology making significant strides is the UTM machine (Unmanned Test Machine), a powerful tool used for a variety of testing, monitoring, and data collection tasks. UTM…

What Makes a Universal Testing Machine Essential? A Universal Testing Machine (UTM) is used to measure the mechanical properties of various materials, including metals, plastics, rubber, textiles, and composites. It performs tension, compression, and flexural tests to determine characteristics like yield strength, tensile strength, elongation, and modulus of elasticity. This…

What Is a Universal Testing Machine? A Universal Testing Machine (UTM) is a mechanical testing device used to determine the tensile, compressive, and flexural strength of materials. The term “universal” indicates its capability to perform multiple types of tests on a wide range of materials, including metals, plastics, rubber, textiles,…

What Is a Digital CTM Machine? A Digital CTM Machine (Compression Testing Machine) is an advanced material testing system used to determine the compressive strength of construction materials such as concrete cubes, cement blocks, bricks, and tiles. It features digital load indicators, automatic data capture, and high-precision sensors that ensure…

Mechanical Testing Machines: Precision Tools for Material Evaluation Mechanical testing machines are essential instruments used across industries to determine the physical and mechanical properties of materials. These machines apply controlled forces to materials such as metals, plastics, ceramics, composites, and elastomers to evaluate their strength, durability, and suitability for specific…

What Is Mechanical Testing Equipment? Mechanical testing equipment refers to a broad range of machines and instruments used to evaluate the physical and mechanical properties of materials. These tests are essential in determining material performance under various conditions such as tension, compression, bending, impact, fatigue, and hardness. The results help…