What is a Cube Testing Machine?

A Cube Testing Machine is a specialized compression testing machine designed to measure the compressive strength of concrete cubes. It is widely used in construction, civil engineering, and quality control laboratories. Concrete cube tests are essential because they ensure that the concrete mix meets the required strength specifications before being used in structures such as bridges, buildings, and roads.

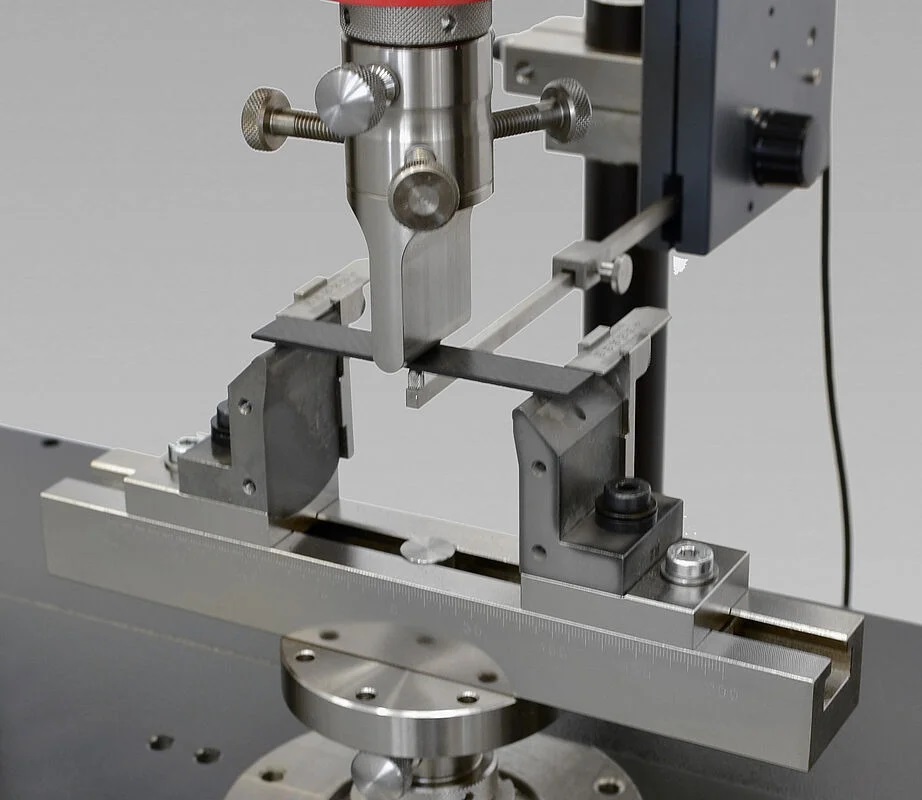

Typically, concrete cubes of 150 mm × 150 mm × 150 mm are prepared and cured for 7, 14, or 28 days. These cubes are then placed in the cube testing machine, which applies a gradually increasing load until the sample fails. The maximum load recorded is used to calculate the compressive strength (in N/mm² or MPa) of the concrete.

Why is Cube Testing Important?

Cube testing is one of the most reliable and straightforward ways to evaluate concrete quality. It helps engineers and contractors to:

Verify whether the concrete mix ratio meets project specifications.

Monitor concrete strength development over time (7, 14, 28-day tests).

Ensure construction safety and compliance with standards like ASTM C39, EN 12390, or IS 516.

Avoid costly failures and ensure long-lasting structures.

In countries like India, UAE, and the UK, cube testing is a mandatory quality control step for most construction projects.

Types of Cube Testing Machines

Cube testing machines can be classified based on their load capacity, control system, and design.

(a) Manual Cube Testing Machine

Operated using a hand pump or screw mechanism.

Suitable for small labs or low-volume testing.

Typically available in 1000kN or 2000kN capacities.

(b) Digital Cube Testing Machine

Features a digital display for direct reading of load and strength.

Often equipped with sensors and load cells for higher accuracy.

Ideal for modern laboratories requiring precise data recording.

(c) Automatic Cube Testing Machine

Controlled via a microprocessor or PC software.

Fully automated loading, testing, and data acquisition.

Suitable for high-volume testing environments.

Cube Testing Machine Price and Selection Guide

The price of a cube testing machine varies depending on the brand, capacity, and level of automation.

Manual machines: Starting from $1,000 – $2,500 (1000kN).

Digital machines: $3,000 – $6,000.

Fully automatic models: $7,000 – $15,000 or more.

Key factors to consider when buying:

Required load capacity (commonly 1000kN, 1500kN, 2000kN).

Compliance with testing standards (ASTM, BS, EN, IS).

Ease of operation and after-sales support.

Availability of spare parts and calibration services.

Cube Testing Machine vs. Universal Testing Machine (UTM)

While Universal Testing Machines can perform multiple tests (tension, compression, bending), a cube testing machine is specifically optimized for concrete compression tests. It is simpler, more robust, and usually cheaper than a UTM.

| Feature | Cube Testing Machine | Universal Testing Machine |

|---|---|---|

| Main Use | Concrete cube compression | Tension, compression, bending |

| Load Range | 1000–3000 kN | 10–2000 kN |

| Cost | Lower | Higher |

| Versatility | Limited | High |

Conclusion

A cube testing machine is an essential piece of equipment for ensuring the safety and reliability of concrete structures. Whether you are a contractor, quality control lab, or civil engineer, investing in a reliable machine is crucial. By choosing a machine that meets international standards and your testing requirements, you can guarantee consistent and accurate concrete strength results.