What Is a Digital CTM Machine?

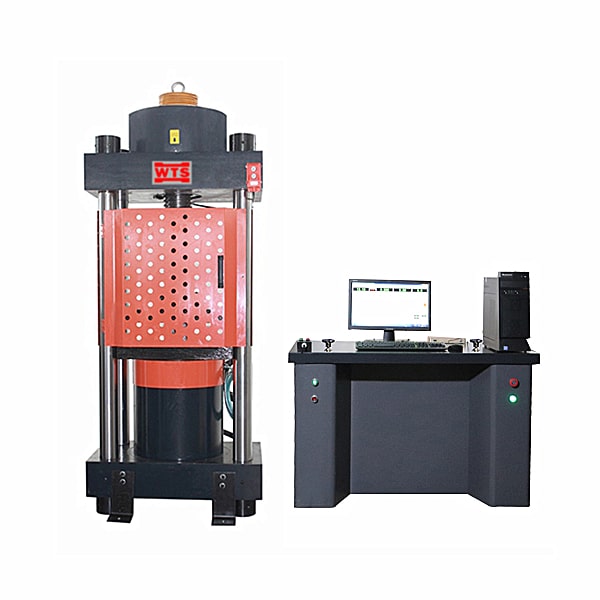

A Digital CTM Machine (Compression Testing Machine) is an advanced material testing system used to determine the compressive strength of construction materials such as concrete cubes, cement blocks, bricks, and tiles. It features digital load indicators, automatic data capture, and high-precision sensors that ensure accurate, efficient, and repeatable testing.

Digital CTM Machines are widely used in civil engineering, quality control laboratories, infrastructure projects, and third-party testing centers. These machines comply with standards such as ASTM, ISO, EN, and IS, and are essential for verifying the strength and performance of building materials under controlled conditions.

Key Features:

- Digital load display with real-time force feedback

- Automatic peak load detection

- USB or RS232 connectivity for data transfer

- Optional PC software and printer integration

- High-speed hydraulic loading system

- Class-1 or better measurement accuracy

Why Choose a Digital CTM Machine Over a Manual One?

Digital CTM Machines offer a range of advantages over analog or manually controlled systems.

Accuracy and Repeatability

Digital CTMs use advanced load cells and microprocessors to ensure accurate readings across multiple tests. They are designed to meet strict calibration standards, including ASTM E4.

Data Logging and Export

Many machines allow users to store multiple test results, export to Excel or PDF, and generate automated reports. This capability is critical for audit trails, compliance, and long-term documentation.

Ease of Use

With intuitive user interfaces, operators can start tests, monitor load-time curves, and view results without extensive training. Touch screens, keypad inputs, and programmable test sequences are common.

Safety Enhancements

Digital CTMs often include overload protection, emergency stop features, and automatic shutoff after test completion, minimizing the risk of damage or injury.

Applications and Specifications of Digital CTM Machines

Digital CTM Machines are manufactured in a variety of capacities, ranging from 100 kN to 3000 kN, to accommodate different testing requirements.

Typical Applications:

| Material | Sample Type | Standard |

|---|---|---|

| Concrete | Cubes, Cylinders | ASTM C39, EN 12390 |

| Cement | Mortar Cubes | ASTM C109 |

| Bricks and Blocks | Solid/Hollow Units | ASTM C67, IS 3495 |

| Tiles | Interlocking/Paving | EN 1339 |

| Soil-Cement | Cylindrical Samples | ASTM D1633 |

Optional Accessories:

- Touch screen HMI controller

- PC data acquisition software

- Thermal or dot-matrix printer

- Wi-Fi/Ethernet module

- Custom test fixtures and platens

Selecting the right configuration depends on the test material, desired capacity, and compliance requirements. For high-strength concrete, a 2000 kN or 3000 kN machine is typically recommended. For standard brick testing, a 300 kN or 600 kN model may suffice.

Conclusion

Digital CTM Machines are an indispensable part of modern material testing labs. They provide high accuracy, seamless data management, and user-friendly operation. Whether in construction, manufacturing, or research, these machines help engineers and technicians meet global testing standards and ensure product quality.

Investing in a Digital CTM Machine not only enhances testing capability but also improves compliance, efficiency, and operational safety across all construction-related industries.