Our Products

FAQ

1.What about the production time?

The production time varies for different products. If the product is in stock, the delivery time is within 5 days. For standard products that are not in stock, the production time is 15 days. The more customization a product requires, the longer the production time, with a maximum of 3 months.

2.Can you provide the related documents?

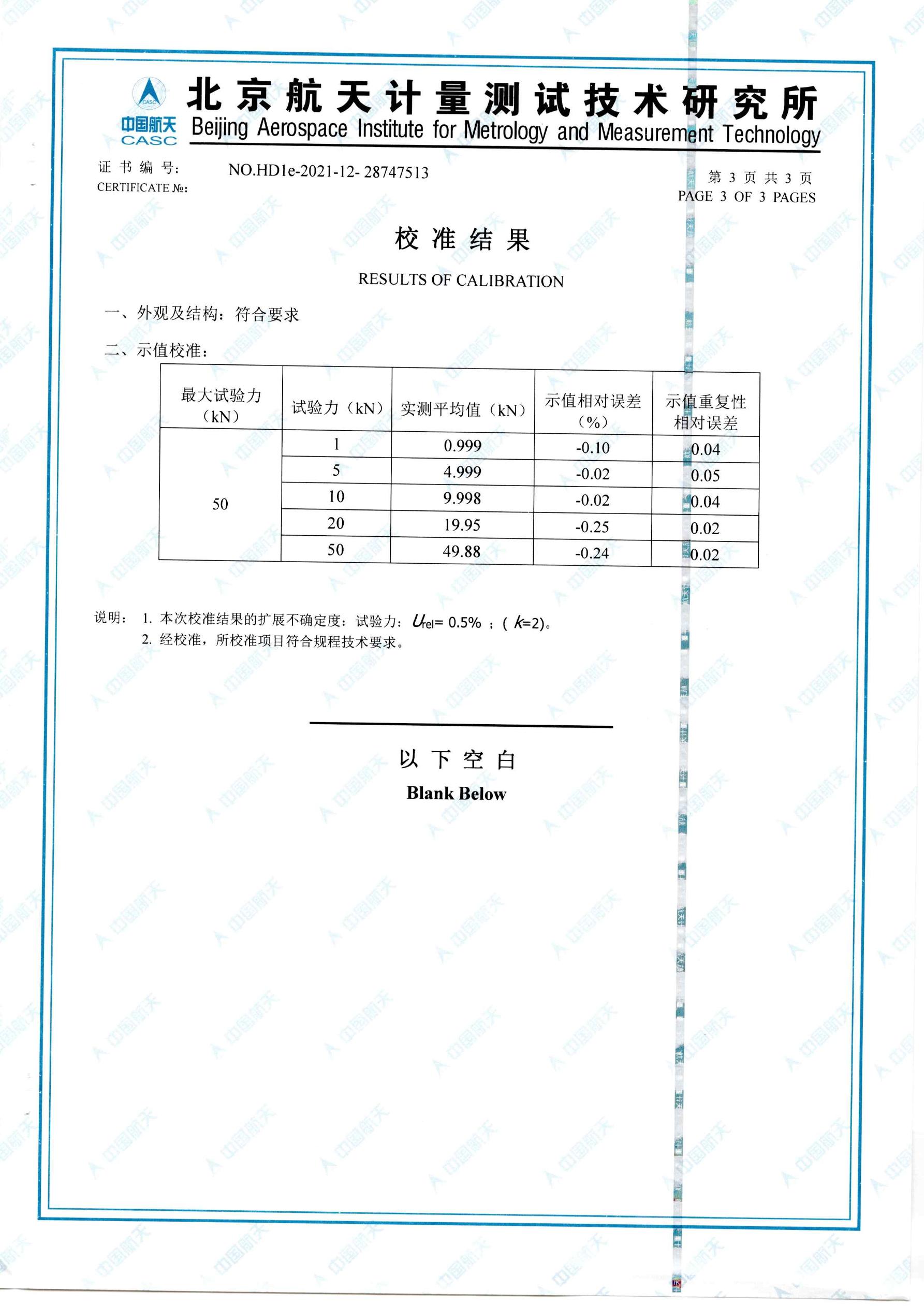

Of course. Regarding certificates, we can provide ISO, CE, and other certificates as needed, or any other documents you require, and we can provide them promptly. As for the product manuals, you can download them from the corresponding section on our website, or you can leave us a message or contact us through WhatsApp, Facebook, LinkedIn, etc.

3.Can you guarantee safe and secure shipping of products?

Our products always use safe and high quality export packing. We use high-quality wood packaging, and we also have long-term partnerships with freight shipping companies. Of course, you are welcome to specify your preferred shipping company.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

1N~1000kN High & Low-Temperature Universal Testing Machine

High and low temperature compression testing machine, mainly testing the pressure resistance (compressive strength) and flexural resistance of various types of concrete, bricks, blocks, cement products, calcined carburizers, calcined carburizers, fireproof materials, engineering materials, and stones. force, bending resistance, stability of physical properties under constant load and mechanical property testing of materials.

Application industries: It is a necessary equipment for laboratories in industries such as highways, railways, bridges, construction, building materials, universities and colleges.

- Tension

- Compression

- Bending

- Shear

- Metals

- Non-metals

- Composite materials

- ASTM D638

- ASTM D1708

- ASTM D412

- ASTM D1876

- ASTM D695

- ASTM D751

- ASTM D882

- ASTM D3330

- ASTM F88

- ISO 37

- ISO 527

- ISO 13934

Specifications

| Model | YAW-600h | YAW-1000h | YAW-2000h | YAW-3000h | YAW-5000h | YAW-10000h | YAW-20000h | Customized |

|---|---|---|---|---|---|---|---|---|

| Maximum test force | 600kN | 1000kN | 2000kN | 3000kN | 5000kN | 10000kN | 20000kN | 300~50000kN |

| Force measurement range | 1%~100%FS without binning throughout the process | |||||||

| Test force indication accuracy | Better than ±1% of the indication value (up to ±0.5%) | |||||||

| Measurement resolution | 1/500000 of the maximum test force | |||||||

| Temperature range | Configurable: Low (-80℃), High (300℃), Combined (-80~300℃), Furnace (up to 1700℃) | |||||||

| Host structure form | Two columns | Four columns | ||||||

| Relative error of worktable speed | Better than ±1% of the indicated value | |||||||

| Pressure plate size | ø160 | ø600 | 600×600 | 1050×1050 | 1500×1500 | Custom made | ||

| Concrete (rock) elastic modulus | Not configurable | Scalable configuration | ||||||

| Rock shearing (45°) device | Not configurable | Scalable configuration | ||||||

| Upper/lower platen adjustment method | Oil cylinder, pressure block, worm gear | |||||||

| Distance between pressure plates (mm) | 300 | 400 | 800 | Customizable | ||||

| Piston stroke (mm) | 140 | 200 | Up to 800 | Customizable | ||||

| Piston displacement speed (mm/min) | 0~100 | 0~80 | 0~50 | |||||

| Test force loading rate | 0.02%~2%FS/s | |||||||

| Power supply voltage | 380V 50Hz (three-phase five-wire system) | |||||||

| Total power (kW) | 4 | 6 | 8 | 12 | 18 | 36 | — | |

| Overall dimensions (mm) | 1000×500×1650 | 720×1300×2300 | 1250×2000×3600 | 2300×1400×3900 | 5600×1750×3900 | 7000×2150×5600 | Customized on demand | |

| Fixture type | W type / Y type | |||||||

Features

The high and low temperature testing machine consists of a main body, a fixture and a movable environmental box.

The main body of the tensile machine adopts a complete set of imported digital AC servo systems and a high-rigidity frame structure.

The high and low temperature test chamber uses double-layer insulated glass doors to facilitate users to observe the test conditions, and uses an all-stainless steel frame and liner, which is not only beautiful but also highly corrosion-resistant.

The overall shape is novel, high precision, low noise and easy to operate.