1N~50kN Peel Testing Machine

- Description

The roller peeling test machine can perform mechanical tests such as roller peeling, flat compression test, system tension and shear test of honeycomb panels, aluminum honeycomb panels, honeycomb aluminum panels, aluminum honeycomb core materials and other materials. The testing machine is also commonly used for metals such as plywood, tape, wires and cables, textiles, waterproof materials, non-woven fabrics, seat belts, rubber, plastics, films, steel wire ropes, steel bars, metal wires, metal foils, metal sheets and metal rod wires. Materials and non-metallic materials and component products are subjected to tests such as tension, compression, bending, tearing, roller peeling, 90° peeling, 180° peeling, shearing, adhesion, pull-out force, extension elongation, etc., and Special mechanical property testing of some products.

Our Products

FAQ

1.What about the production time?

The production time varies for different products. If the product is in stock, the delivery time is within 5 days. For standard products that are not in stock, the production time is 15 days. The more customization a product requires, the longer the production time, with a maximum of 3 months.

2.Can you provide the related documents?

Of course. Regarding certificates, we can provide ISO, CE, and other certificates as needed, or any other documents you require, and we can provide them promptly. As for the product manuals, you can download them from the corresponding section on our website, or you can leave us a message or contact us through WhatsApp, Facebook, LinkedIn, etc.

3.Can you guarantee safe and secure shipping of products?

Our products always use safe and high quality export packing. We use high-quality wood packaging, and we also have long-term partnerships with freight shipping companies. Of course, you are welcome to specify your preferred shipping company.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Features

The roller peeling test machine can perform mechanical tests such as roller peeling, flat compression test, system tension and shear test of honeycomb panels, aluminum honeycomb panels, honeycomb aluminum panels, aluminum honeycomb core materials and other materials. The testing machine is also commonly used for metals such as plywood, tape, wires and cables, textiles, waterproof materials, non-woven fabrics, seat belts, rubber, plastics, films, steel wire ropes, steel bars, metal wires, metal foils, metal sheets and metal rod wires. Materials and non-metallic materials and component products are subjected to tests such as tension, compression, bending, tearing, roller peeling, 90° peeling, 180° peeling, shearing, adhesion, pull-out force, extension elongation, etc., and Special mechanical property testing of some products.

- Tension

- Compression

- Bending

- Shear

- Metals

- Non-metals

- Composite materials

- ASTM D638

- ASTM D1708

- ASTM D412

- ASTM D1876

- ASTM D695

- ASTM D751

- ASTM D882

- ASTM D3330

- ASTM F88

- ISO 37

- ISO 527

- ISO 13934

Specifications

| Model | WDW-5 | WDW-10 | WDW-20 | WDW-50 |

|---|---|---|---|---|

| Maximum test force | 5 kN | 10 kN | 20 kN | 50 kN |

| Force measurement range | 0.4% – 100% FS without binning throughout the process | |||

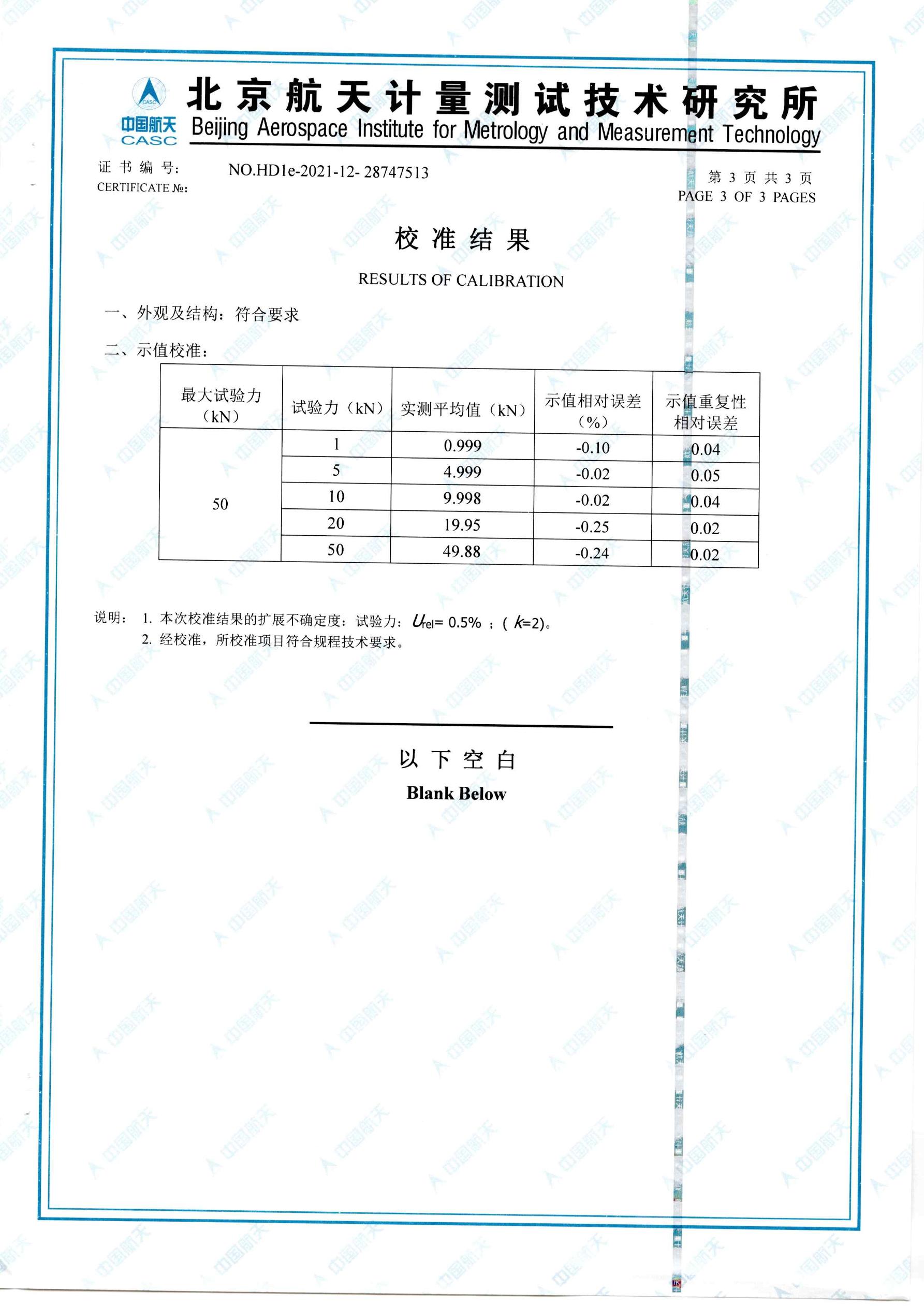

| Test force indication accuracy | Better than ±1% of the indication value (precision level can reach ±0.5%) | |||

| Deformation accuracy | Better than ±1% of the indication value | |||

| Crossbeam displacement measurement (mm) | Resolution 0.001 | |||

| Deformation range | 1% – 100% | |||

| Stripped form | Roller peeling, 90° peeling, 180° peeling | |||

| Large deformation indication accuracy | Within ±1% of the indication value | |||

| Displacement resolution | Resolution 0.001 | |||

| Displacement rate adjustment range | (0.001–500) mm/min, arbitrarily set. Higher speed can be customized. | |||

| Displacement rate spatial accuracy | ≤ ±1% | |||

| Stretch stroke (mm) | 600 (can be lengthened) | 800 (can be lengthened) | 800 (can be lengthened) | 800 (can be lengthened) |

| Crossbeam moving space (mm) | 900 (can be extended) | 1150 (can be lengthened) | 1200 (can be lengthened) | 1200 (can be lengthened) |

| Host size (mm) | 400 × 300 × 1250 | 640 × 330 × 1550 | 855 × 400 × 1980 | 855 × 400 × 1980 |

| Testing machine weight (kg) | About 60 | About 150 | About 450 | About 450 |

| Motor power (kW) | 0.75 | 1 | 1.5 | 1.5 |

| Testing machine auxiliary tools | Peeling aids, stretching aids, compression aids, bending aids and other aids (optional) can be customized | |||

| Safety protection | Limit protection, full-scale overload protection, overcurrent and overvoltage protection, emergency switch protection | |||