Our Products

FAQ

1.What about the production time?

The production time varies for different products. If the product is in stock, the delivery time is within 5 days. For standard products that are not in stock, the production time is 15 days. The more customization a product requires, the longer the production time, with a maximum of 3 months.

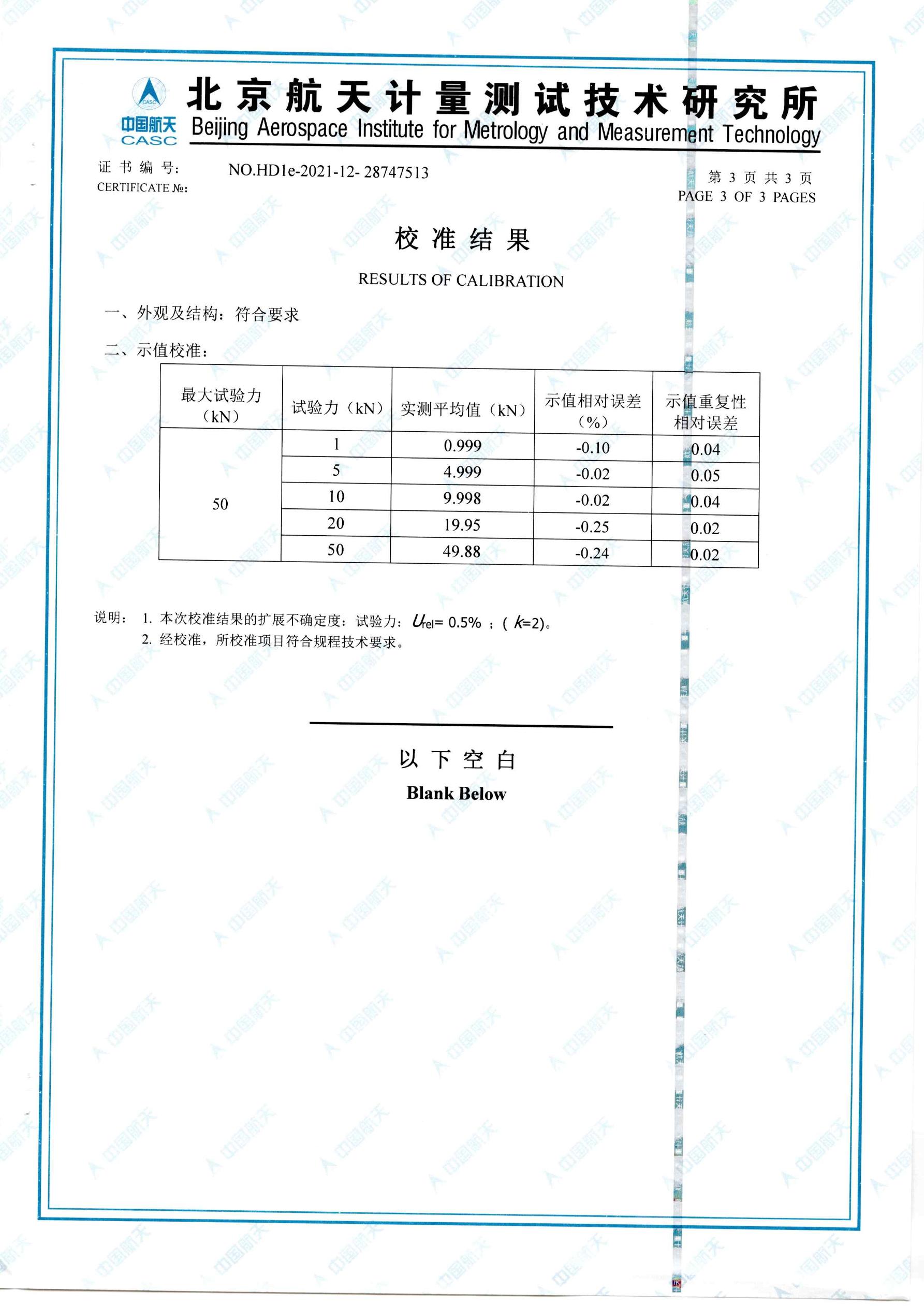

2.Can you provide the related documents?

Of course. Regarding certificates, we can provide ISO, CE, and other certificates as needed, or any other documents you require, and we can provide them promptly. As for the product manuals, you can download them from the corresponding section on our website, or you can leave us a message or contact us through WhatsApp, Facebook, LinkedIn, etc.

3.Can you guarantee safe and secure shipping of products?

Our products always use safe and high quality export packing. We use high-quality wood packaging, and we also have long-term partnerships with freight shipping companies. Of course, you are welcome to specify your preferred shipping company.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

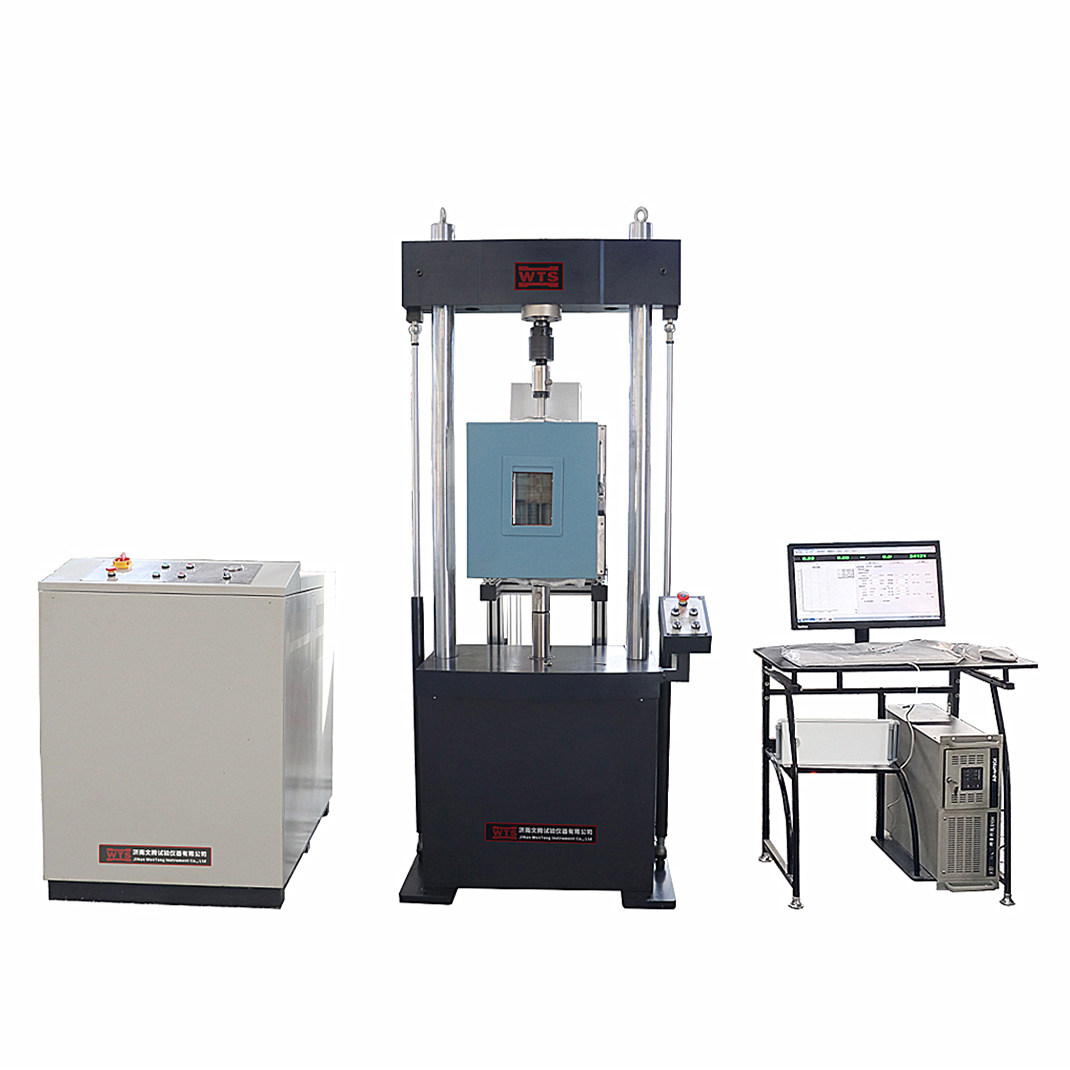

20kN Fatigue Testing Machine

PDW-series fatigue testing machines are mainly used to test the dynamic and static mechanical properties of various materials, components, elastomers, rubber elastomers and shock absorbers. It can conduct tension, compression, bending, low-cycle and high-cycle fatigue, crack growth, and fracture mechanics tests under sine waves, triangle waves, square waves, trapezoidal waves, ramp waves, and user-defined waveforms. Environmental chambers such as high-temperature furnaces, low-temperature chambers, and corrosion chambers can be equipped according to special requirements to complete mechanical testing of materials in different environments. It is widely used in automobile parts, rail vehicles, aerospace, ships, military industry and other fields.

- Tension

- Compression

- Bending

- Shear

- Metals

- Non-metals

- Composite materials

- ASTM D638

- ASTM D1708

- ASTM D412

- ASTM D1876

- ASTM D695

- ASTM D751

- ASTM D882

- ASTM D3330

- ASTM F88

- ISO 37

- ISO 527

- ISO 13934

Specifications

| Model | PDW-5/10 | PDW-20 | Customized on demand |

|---|---|---|---|

| Maximum static test force | 5/10kN | 20kN | ≤20kN |

| Maximum dynamic load | ±5/10kN | ±20kN | ≤20kN |

| Test force indication accuracy | Better than ±0.5% of the indicated value | ||

| Deformation accuracy | Better than ±0.5% of the indicated value | ||

| Coaxiality of upper and lower grips | <5% | ||

| Dynamic indication accuracy | <1% | ||

| Equipment noise | <68dB | ||

| Load range | 10%, 20%, 50%, 100% | ||

| Actuator piston stroke (mm) | ±70 (±50) | ||

| Frequency Range | 0.01—100Hz (can be customized) | ||

| Test waveform (basic configuration) | Sine wave, triangle wave, square wave | ||

| Test waveform (extended configuration) | Trapezoidal wave, ramp wave, block wave, random wave | ||

| Standard mainframe | Double columns, actuator on the top or double columns, actuator on the bottom | ||

| Control method | Fully automatic displacement and load control, smooth switching between modes | ||

| Vertical test space | Can be automatically adjusted | ||

| Test amplitude | Determine the frequency and amplitude according to the displacement of the hydraulic servo pump station | ||

| Column spacing (mm) | 400 / 600 | ||

| Stretch space (excluding clamps) (mm) | 500 / 750 | ||

| Test software | Work under Windows Chinese environment, and the test process is all under computer control | ||

| Safety protection | Limit protection, full-scale overload protection, overcurrent and overvoltage protection, emergency switch protection | ||

| Voltage | Conventional voltage 220V/380V, can also be configured according to the standard voltage of the country where it is used | ||

Features

1. The actuator adopts a double-acting oil cylinder design, with reasonable space design and easy operation;

2. The lifting, locking, and sample clamping of the moving beam are all operated by buttons, which is flexible and convenient;

3. Automatic control, measurement, data collection and processing, drawing and printing test curves and test reports;

4. The measurement and control system is automatically calibrated and zeroed;

5. Stepless speed regulation, the control speed and control mode can be smoothly switched and maintained during the test process;

6. Data storage and curve amplification, different test curves can be displayed arbitrarily during the test process;

7. During the automatic operation of the program, it can be converted to manual control at any time, and the control method and control speed can be manually adjusted;

8. Test force overload automatic protection function, the protection range can be set arbitrarily;