50~500kN Creep Testing Machine

Maximum Test Force: 50~500kN

- Description

The durable creep testing machine meets the requirements of GB/T2039-1997 Metal Tensile Creep and Durability Test Methods and HB5151-1996 Metal High Temperature Tensile Creep Test Methods. It is mainly used for testing metal and non-metallic materials in normal or high temperature environments. Creep, durability, stress relaxation tests; it can also complete high-temperature short-time tensile tests, cyclic loading tests, low-cycle cycles and other tests. It is suitable for metallurgical departments, scientific research institutions, quality inspection departments, aerospace, vehicle manufacturing, machinery manufacturing, petroleum Commonly used equipment for material performance testing and research in chemical industry, building materials, colleges and universities and related mining enterprises.

Our Products

FAQ

1.What about the production time?

The production time varies for different products. If the product is in stock, the delivery time is within 5 days. For standard products that are not in stock, the production time is 15 days. The more customization a product requires, the longer the production time, with a maximum of 3 months.

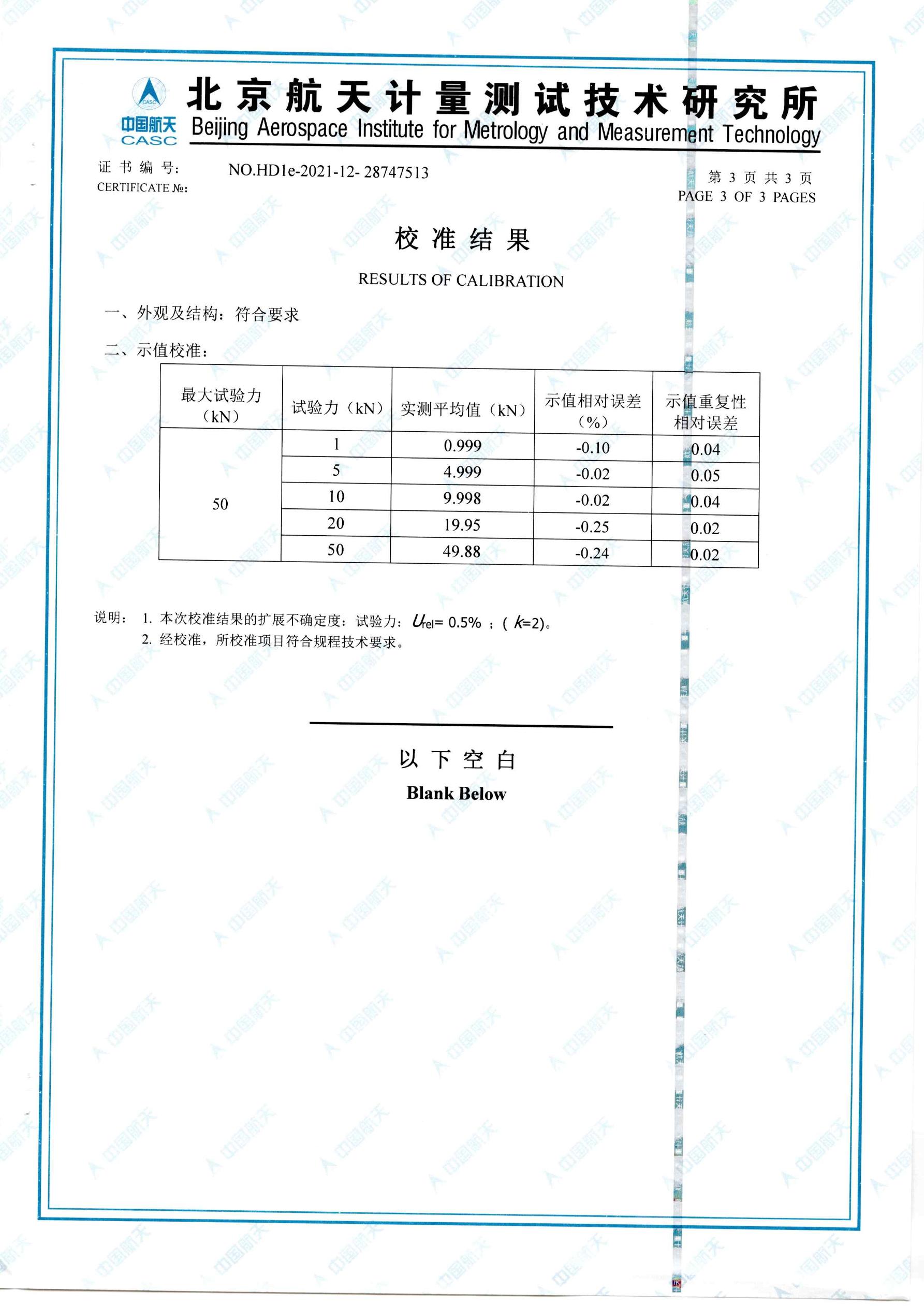

2.Can you provide the related documents?

Of course. Regarding certificates, we can provide ISO, CE, and other certificates as needed, or any other documents you require, and we can provide them promptly. As for the product manuals, you can download them from the corresponding section on our website, or you can leave us a message or contact us through WhatsApp, Facebook, LinkedIn, etc.

3.Can you guarantee safe and secure shipping of products?

Our products always use safe and high quality export packing. We use high-quality wood packaging, and we also have long-term partnerships with freight shipping companies. Of course, you are welcome to specify your preferred shipping company.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Features

1. It can work on a single unit or in a cluster of 10 units;

2. The high-temperature clamping device has a threaded connection structure, a shoulder-type hanging structure, and a plate-type pin structure to choose from; each specification of specimen needs to be paired with a corresponding fixture and a high-temperature extensometer;

3. High-temperature clamping devices/lead rods and K-type and S-type thermocouples made of stainless steel, K3, K465 high-temperature alloy, DZ alloy, DD alloy and other materials can be selected from low to high according to different temperature requirements;

4. Using temperature compensation technology, the test system does not require water cooling.

5. UPS power supply is an optional accessory, which can ensure that the testing machine can continue to work, store test data, and unload specimens in a short period of time in the event of a power outage to protect the testing machine.

6. The photoelectric position indicating device makes the test operation simple and convenient.

- Tension

- Compression

- Bending

- Shear

- Metals

- Non-metals

- Composite materials

- ASTM D638

- ASTM D1708

- ASTM D412

- ASTM D1876

- ASTM D695

- ASTM D751

- ASTM D882

- ASTM D3330

- ASTM F88

- ISO 37

- ISO 527

- ISO 13934

Specifications

| Model | RDW-10 | RDW-20 | RDW-30 | RDW-50 | RDW-100 | RDW-300 | RDW-500 |

|---|---|---|---|---|---|---|---|

| Maximum test force | 10kN | 20kN | 30kN | 50kN | 100kN | 300kN | 500kN |

| Force measurement range | 0.4%~100%FS (full scale) | ||||||

| Test force indication accuracy | Better than ±1% (up to ±0.5%) | ||||||

| Force resolution | ±500000 codes, no binning, constant resolution | ||||||

| Deformation measurement error | ±0.5% | ||||||

| Deformation range | 0~10mm | ||||||

| Deformation resolution | ±500000 codes, no binning, constant resolution | ||||||

| Tie rod stroke | 200mm | ||||||

| Rod speed | 0.01~50mm/min | ||||||

| Host dimensions (mm) | 710×540×2200 | 730×540×2400 | 950×740×3200 | ||||

| Host weight | 400kg | 500kg | 600kg | 1000kg | 1200kg | ||

| Temperature range | 300~1600℃ | ||||||

| Temperature ladder | 3℃ | ||||||

| Temperature fluctuation | ±2℃ | ||||||

| Furnace size | Φ80×Φ340mm (customizable) | ||||||

| Bore size | Φ320×Φ440mm (customizable) | ||||||

| Thermogenic ability | 1200℃ | ||||||

| Average tropic zone | 150mm | ||||||