Our Products

FAQ

1.What about the production time?

The production time varies for different products. If the product is in stock, the delivery time is within 5 days. For standard products that are not in stock, the production time is 15 days. The more customization a product requires, the longer the production time, with a maximum of 3 months.

2.Can you provide the related documents?

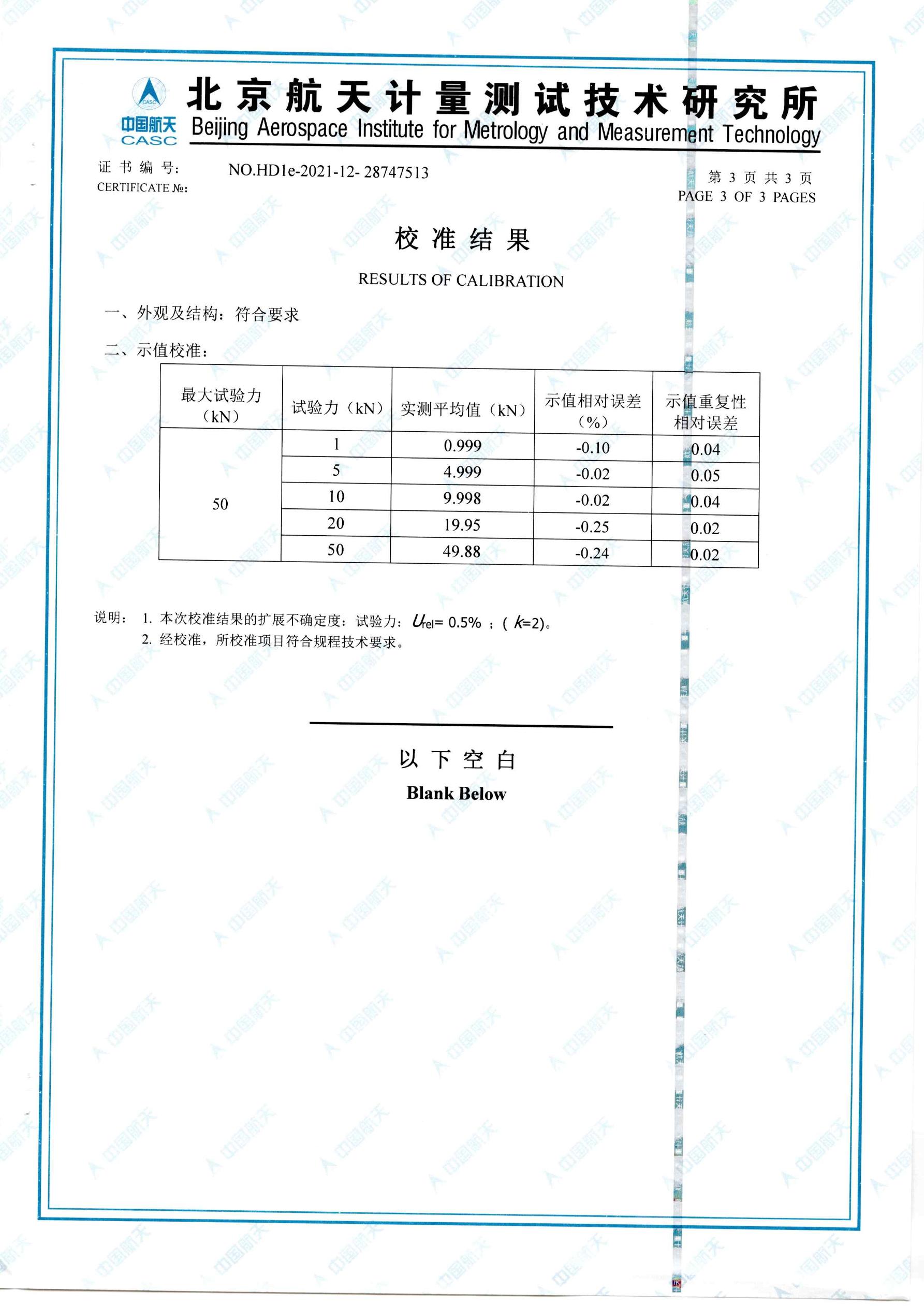

Of course. Regarding certificates, we can provide ISO, CE, and other certificates as needed, or any other documents you require, and we can provide them promptly. As for the product manuals, you can download them from the corresponding section on our website, or you can leave us a message or contact us through WhatsApp, Facebook, LinkedIn, etc.

3.Can you guarantee safe and secure shipping of products?

Our products always use safe and high quality export packing. We use high-quality wood packaging, and we also have long-term partnerships with freight shipping companies. Of course, you are welcome to specify your preferred shipping company.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

1000kN Hydraulic Universal Testing Machine

The hydraulic universal testing machine can meet the various standard tests in the national standards for metal and non-metal tensile tests, and can also perform tensile, compression, bending, shear and other types of tests on different materials or products in accordance with other standards. The tensile strength, yield strength, specified non-proportional extension strength, elastic modulus and other performance indicators of the measured material can be obtained, and closed-loop control such as constant rate loading, constant rate deformation, and constant rate displacement can be realized, and materials or products can be processed. Process qualification performance verification test.

Specifications

| Model | WAW-300B/E | WAW-600B/E | WAW-1000B/E | WAW-2000E | Customized on demand |

|---|---|---|---|---|---|

| Maximum test force | 300kN | 600kN | 1000kN | 2000kN | 100~4000kN |

| Force measurement range | 1%~100%FS (full scale) | ||||

| Test force indication accuracy | ≤1% | ||||

| Stress rate control adjustment range | 1MPa/s~45MPa/s | ||||

| Crossbeam displacement adjustment speed (mm/min) | 170 | 220 | 190 | 160 | — |

| Deformation range | 1%~100%FS (full scale) | ||||

| Displacement resolution | 0.001 | ||||

| Displacement control speed range (mm/min) | 0.01~200 | 0.01~100 | 0.01~70 | 0.01~50 | — |

| Stress/strain/displacement maintain control accuracy | ≤1% | ||||

| Cross beam position adjustment method | Sprocket drive | ||||

| Maximum span of bending support roller (mm) | 400 | 401 | 402 | 403 | Custom |

| Tensile test space (mm) | 600 | 700 | 700 | 800 | Custom |

| Compression test space (mm) | 550 | 600 | 600 | 650 | Custom |

| Host size (mm) | 750×530×1930 | 840×600×2130 | 910×640×2250 | 1170×800×2750 | Custom made |

| Testing machine weight (kg) | about 1200 | about 1700 | about 2100 | about 5000 | Custom |

| Motor power (kw) | 1.5 | 2 | 2 | 3.5 | Custom |

| Oil source console size (mm) | (L×W×H) 1200×600×750 | ||||

| Test model | Microcomputer controlled electro-hydraulic servo, microcomputer screen display, digital display | ||||

Features

1. The hydraulic universal testing machine is mainly used for testing metal materials such as smooth round steel bars, ribbed steel bars, straight steel bars, coiled steel bars, metal plates, metal bars, cables and ropes, castings and forgings, bolt fasteners, metal pipes, etc. , and non-metallic materials can be tested and researched on tensile tests, compression tests, bending tests, shear tests, etc., and other mechanical properties at room temperature.

2. The testing machine is equipped with a computer, printer, electronic extensometer, photoelectric encoder and general testing software, which can accurately measure the tensile strength, tensile strength, yield strength, specified non-proportional elongation strength, elongation and elastic modulus of metal materials. Quantitative equality.

3. Experimental results can be queried and printed (force-displacement, force-deformation, stress-time, stress-strain, force-time, deformation-time, force-displacement, displacement-time) eight kinds of curves and related experimental data, with The software self-test function can self-diagnose faults. Please refer to the software description for details. It is an ideal testing design for industrial and mining enterprises, scientific research units, colleges and universities, engineering quality supervision stations and other departments.

People who viewed this item also viewed

100KN-3000KN-Hydraulic-Universal-Testing-Machine

300kN-Hydraulic-Universal-Testing-Machine

600kN-Hydraulic-Universal-Testing-Machine