Our Products

FAQ

1.What about the production time?

The production time varies for different products. If the product is in stock, the delivery time is within 5 days. For standard products that are not in stock, the production time is 15 days. The more customization a product requires, the longer the production time, with a maximum of 3 months.

2.Can you provide the related documents?

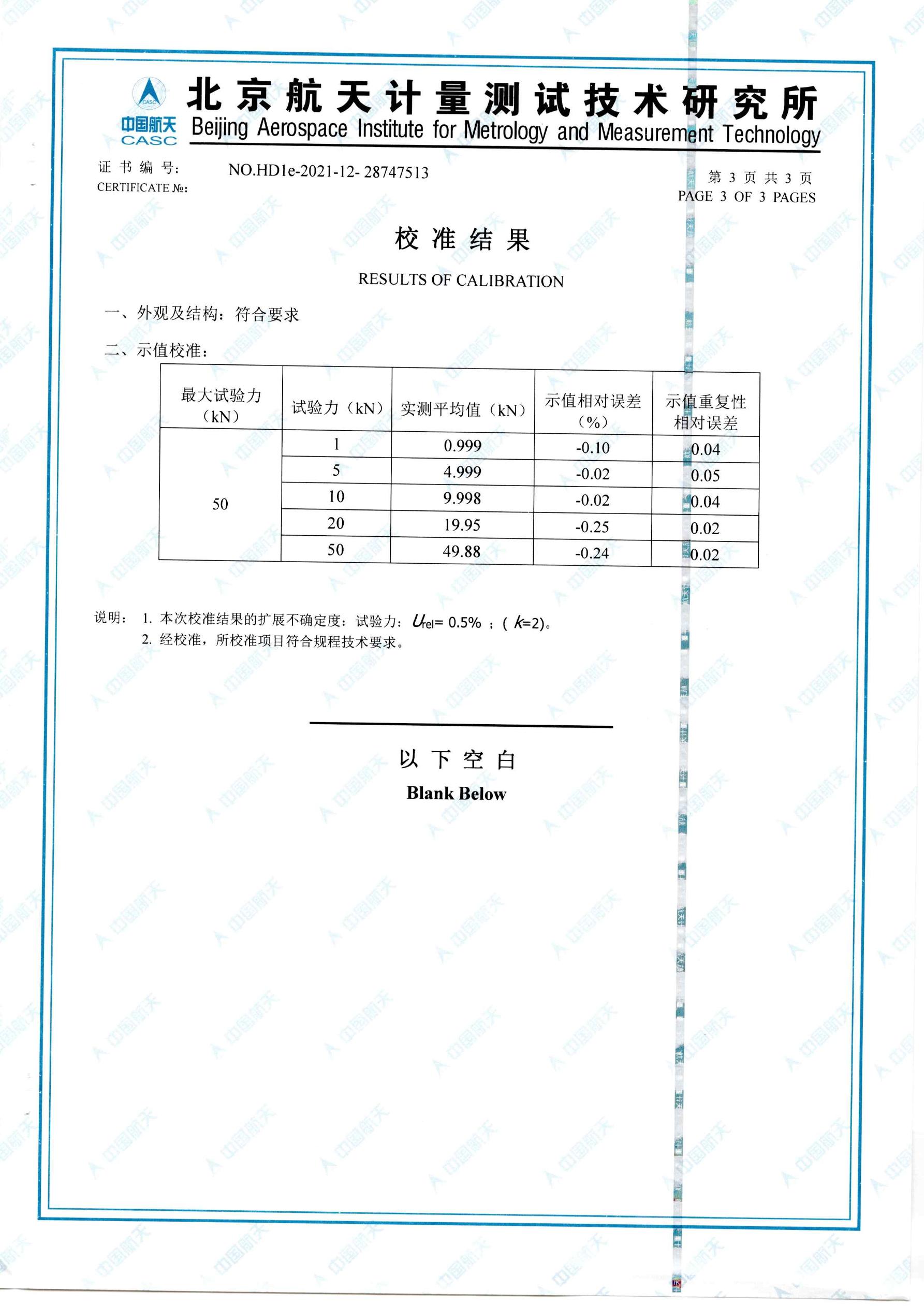

Of course. Regarding certificates, we can provide ISO, CE, and other certificates as needed, or any other documents you require, and we can provide them promptly. As for the product manuals, you can download them from the corresponding section on our website, or you can leave us a message or contact us through WhatsApp, Facebook, LinkedIn, etc.

3.Can you guarantee safe and secure shipping of products?

Our products always use safe and high quality export packing. We use high-quality wood packaging, and we also have long-term partnerships with freight shipping companies. Of course, you are welcome to specify your preferred shipping company.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Small Universal Tensile Testing Machine

The high-precision micro tensile testing machine is a micro mechanical performance testing system that can achieve many functions that other instruments cannot achieve.

Smaller volume, better force resolution, easier test settings and visual effects, it is mainly used for testing and researching mechanical performance indicators such as tension, compression, and bending of various metals, non-metals, and composite materials.

It has the functions of small size, easy portability, 360-degree full transparency, high precision, low noise, simple operation, continuously adjustable test speed, and automatic shutdown when the sample is broken.

- Tension

- Compression

- Bending

- Shear

- Metals

- Non-metals

- Composite materials

- ASTM D638

- ASTM D1708

- ASTM D412

- ASTM D1876

- ASTM D695

- ASTM D751

- ASTM D882

- ASTM D3330

- ASTM F88

- ISO 37

- ISO 527

- ISO 13934

Specifications

| Model | WDW-50E | WDW-100E | WDW-150E | WDW-200E | WDW-300E | WDW-600E |

|---|---|---|---|---|---|---|

| Maximum test force | 50kN | 100kN | 150kN | 200kN | 300kN | 600kN |

| Force measurement range | 0.4%~100%FS without binning throughout the process | |||||

| Test force indication accuracy | Better than ±1% of the indication value (precision level can reach ±0.5%) | |||||

| Deformation accuracy | Better than ±1% of the indication value | |||||

| Crossbeam displacement | Resolution 0.001 | |||||

| Deformation range | 2%-100% | |||||

| Measuring range | 10-800 (optional) | |||||

| Accuracy | Within ±1% of the indication value | |||||

| Displacement resolution (n) | Resolution 0.001 | |||||

| Displacement rate adjustment range | (0.001-500) mm/min can be set arbitrarily. Higher speed can be customized. | 0.001~250mm/min | ||||

| Displacement rate spatial accuracy | ≤±1% | |||||

| Stretch stroke (mm) | 800 | 800 | 650 | 600 | 600 | 600 |

| Test space (mm) | 1200 | 1200 | 1300 | 1400 | 1400 | 1450 |

| Host size (mm) | (855 × 400 × 1980) | (905 × 500 × 2000) | (955 × 500 × 2190) | (1104 × 600 × 2430) | (1104 × 600 × 2430) | (1365 × 870 × 2500) |

| Testing machine weight (kg) | about 450 | about 600 | about 800 | About 1250 | About 1250 | about 2500 |

| Motor power (kw) | 1 | 1.5 | 2 | 2.5 | 2.5 | 4.5 |

| Testing machine auxiliary tools | Stretching aids, compression aids, bending aids and other aids (optional) can be customized | |||||

| Testing machine style | Floor-to-ceiling door type | |||||

Features

The system can record and output force-displacement data and test images in real-time, and the control software supports load control and displacement control solutions. After establishing the scheme, you can use the template function to quickly load the required test parameters. As the test runs, the software provides real-time results graphs and a live video feed to allow users to monitor test progress.

1. Adopt a fully digital AC servo speed control system and servo motor as the drive system, with high-speed control accuracy and stable performance.

2. Microcomputer control and data processing software automatically collects and processes test data, draws various curves, and prints test reports;

3. A good humanized design makes the test operation easier, and the test operations can be automatically completed on the computer through the mouse.

4. This machine fully meets the requirements of national standards and can conduct testing and data processing according to GB, ISO, JIS, ASTM, DIN, and various standards provided by users.

5. It has good scalability and can cope with various tests of different samples by changing the fixture.

6. It has three control modes: stress, strain, and displacement. The control modes can be switched randomly.

7. It has functions such as mechanical limit protection, overload protection, overcurrent protection, and leakage protection.