What is Ultimate Tensile Strength (UTS)?

Ultimate Tensile Strength (UTS) refers to the maximum stress that a material can withstand before breaking when subjected to tension. It is a critical mechanical property for metals, plastics, composites, rubber, and other engineering materials.

UTS is usually measured in:

MPa (Megapascals)

N/mm² (Newton per square millimeter)

For example:

Mild steel: ~400–600 MPa

High-strength steel alloys: >1000 MPa

Plastics: typically much lower than metals

How to Measure Ultimate Tensile Strength?

The most reliable way to measure UTS is by using a Universal Testing Machine (UTM).

A UTM applies a controlled tensile force to a specimen until it fractures, recording both the applied load and the specimen’s elongation. The point at which the specimen breaks corresponds to its Ultimate Tensile Strength.

Key Components of UTM for UTS Testing:

Load Cell – measures the tensile force accurately

Grips/Fixtures – hold the specimen securely during testing

Extensometer – measures elongation or strain

Software – generates stress-strain curves, UTS, yield strength, and modulus

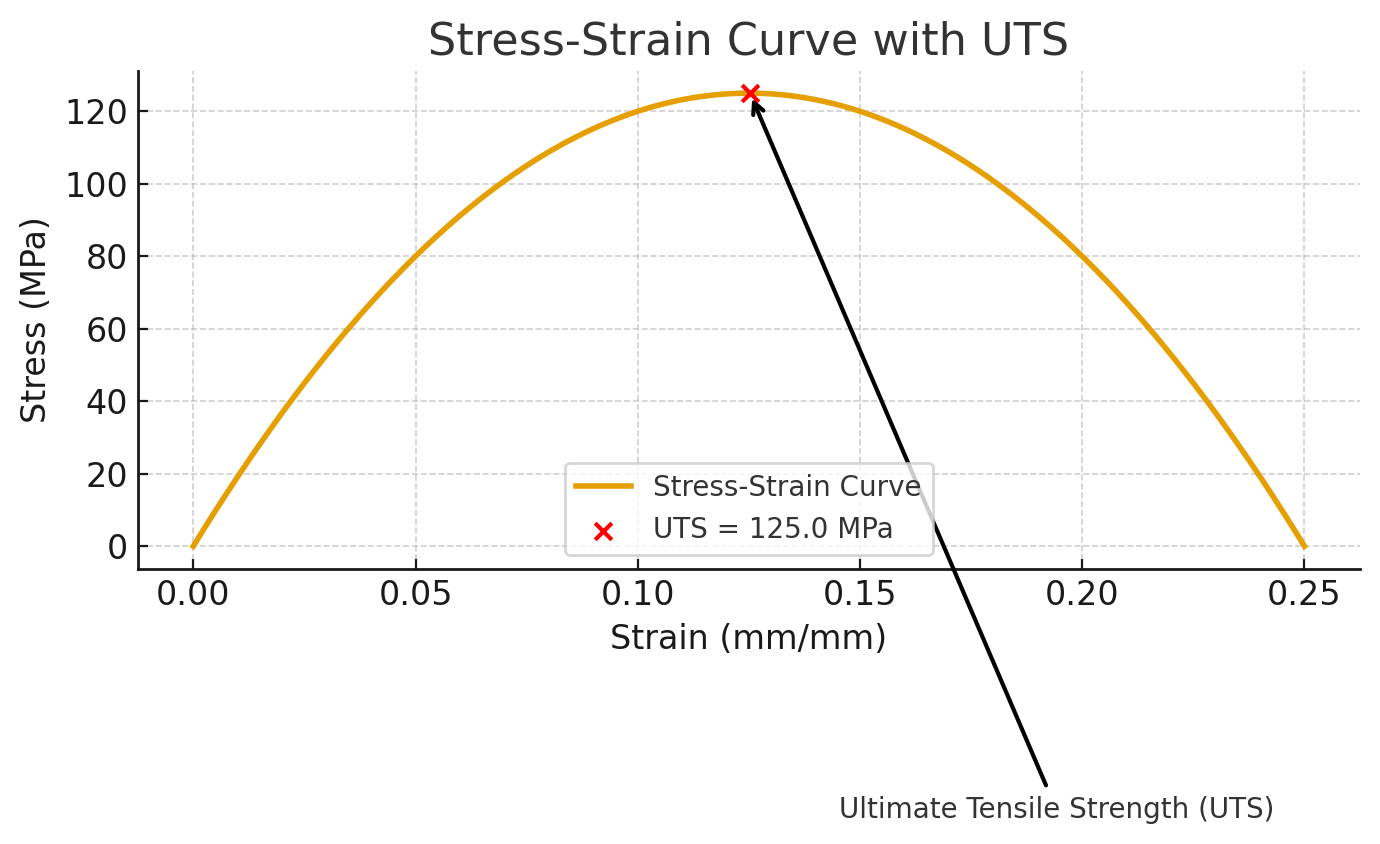

Stress-Strain Curve and UTS

When performing a tensile test, the UTM produces a stress-strain curve.

The peak point of the curve indicates the UTS.

Other parameters such as yield strength, elongation at break, and Young’s modulus can also be derived.

Applications of UTS Testing

Measuring Ultimate Tensile Strength with a Universal Testing Machine is widely used in:

Metals & Alloys – quality control in steel, aluminum, copper production

Plastics & Polymers – following standards like ASTM D638 and ISO 527

Rubber & Elastomers – tensile durability testing

Composites – aerospace, automotive, and sports equipment materials

Construction Materials – concrete, geosynthetics, and building components

Benefits of Using UTM for UTS Testing

Provides accurate, repeatable results

Complies with international standards (ASTM, ISO, GB/T)

Supports R&D, quality assurance, and certification

Ensures safety and reliability of products in critical industries

Conclusion

Ultimate Tensile Strength (UTS) is one of the most important mechanical properties for understanding how materials perform under tension. A Universal Testing Machine (UTM) is the standard equipment for accurately determining UTS, helping industries maintain product quality, safety, and compliance with global testing standards.

If your business involves materials testing, R&D, or quality control, investing in a high-quality Universal Testing Machine for UTS testing is essential.